Exhaust Flexible Pipe With Nipple

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

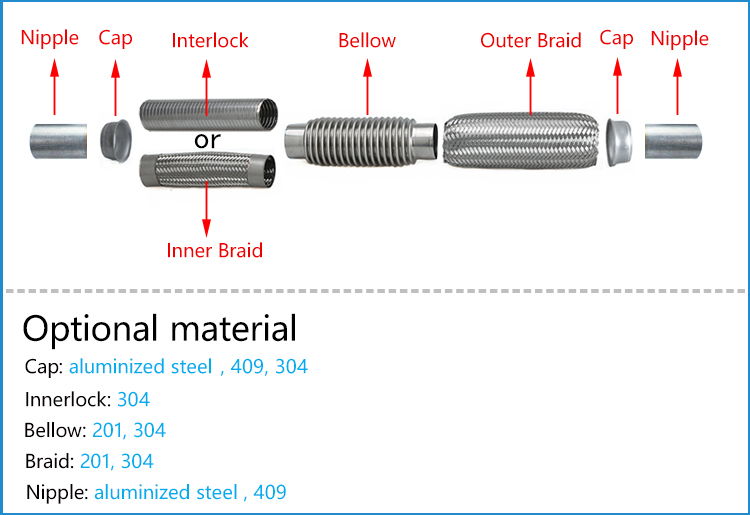

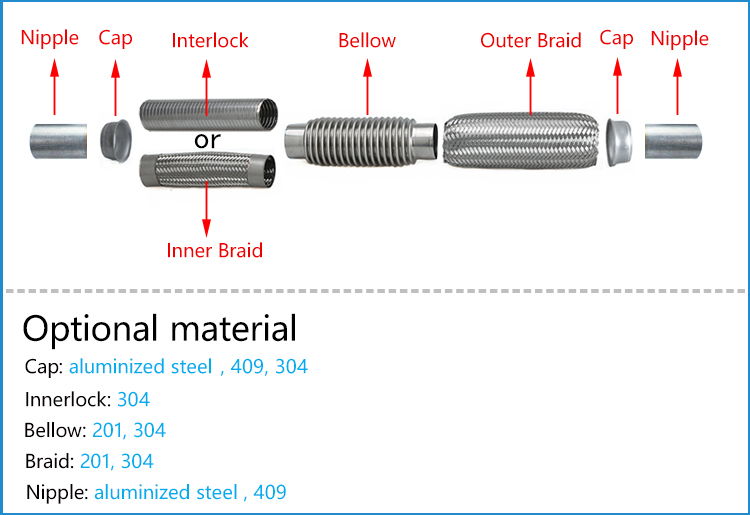

| Application Scenarios: Used in automotive exhaust systems, especially where weld-on integration is required between engine manifolds, mufflers, or converters. Manufacturing Processes: Hydraulic pressure forming with water medium ensures uniform corrugation. Nipples are precisely welded to both ends for secure connection. Features: Enhanced weldability, strong sealing, reduced installation misalignment. Stable under thermal cycling. Customization: Available in various lengths, diameters, materials (304/316/201), nipple types, and wall thickness. | |||||||||

Product Introduction

This type of exhaust flexible pipe with nipple is designed for system integrators or fabricators who require strong weld-on connectivity between exhaust segments. The welded nipple ends provide a secure and stable transition, improving assembly efficiency and minimizing the risk of leaks at high temperature or pressure.

Manufactured using precision hydroforming technology, the corrugated bellows maintain consistent geometry to resist fatigue. By applying nipples with matching steel grades, the welding interface ensures metallurgical compatibility and extended service life.

Material and Compatibility

All nipple flex pipes are primarily constructed using SS304 stainless steel for base resistance to oxidation and corrosion under exhaust gas exposure. The outer braid ensures physical protection and vibration resistance, while the welded nipples improve integration for welding or clamp-on systems.Alternate grades such as SS316 or carbon steel nipples are optional, based on environmental exposure or design needs.

Use Case & Integration Tips

In automotive, these pipes are commonly used in high-vibration zones or pre-silencer joints. For OEM use, nipple-ended hoses reduce secondary fixture costs and speed up assembly line production. For aftermarket installations, they provide a reliable weld-ready solution.

We have different types of exhaust flexible pipe, basic exhaust flexible pipe, exhaust flexible pipe with interlock, exhaust flexible pipe with innerbraid and exhaust flexible pipe with nipple, The exhaust pipe with nipple can help customers better match the use scenario and install quickly. In addition, we support the customization of products, including trademark lettering and packaging customization, as long as you ask questions, we will solve the problem for you.

Technical Specs Table

| Parameter | Specification |

|---|---|

| Material | Stainless Steel 304 |

| Braid Type | Single Layer Outer Braid |

| Nipple Type | Round Welded End |

| Length | 100mm – 500mm (custom) |

| Diameter | 38mm – 76mm standard |

| MOQ | 50 pcs |

| Packaging | Pallet or Carton Bulk Supply |

FAQs

Q1: Can we use the nipple flex pipe for turbocharged engines?

Yes. It is suitable for high-pressure exhaust flow and offers improved vibration isolation.

Q2: Can nipple materials differ from the bellows?

Yes, but we recommend material consistency to avoid heat expansion mismatch and galvanic corrosion.

Q3: Is it possible to customize the cap type or weld seam?

Absolutely. We offer MIG/TIG welds, K1/K2 caps, and laser-engraved ends.

Q: Can I order a sample? Is the quality guaranteed?

A: Absolutely,we provide samples and various test reports,and we will regularly do quantitative exhaust pipe corrosion resistance,anti-torque and other testing experiments,packaging will also do manual screening,all of which is to ensure the quality of each exhaust pipe,even if the exhaust pipe out of the problem,we will return after sale,please rest assured purchase.

Q: Do you have any experience in large volume cooperation?

A: We have large-scale pipeline project cooperation in China,and our customers all over the world,shipments can be fully guaranteed,we also often participate in the international large auto parts machinery exhibition,so whether online or offline,whether production or after-sales,we have quite good experience.

Product Introduction

This type of exhaust flexible pipe with nipple is designed for system integrators or fabricators who require strong weld-on connectivity between exhaust segments. The welded nipple ends provide a secure and stable transition, improving assembly efficiency and minimizing the risk of leaks at high temperature or pressure.

Manufactured using precision hydroforming technology, the corrugated bellows maintain consistent geometry to resist fatigue. By applying nipples with matching steel grades, the welding interface ensures metallurgical compatibility and extended service life.

Material and Compatibility

All nipple flex pipes are primarily constructed using SS304 stainless steel for base resistance to oxidation and corrosion under exhaust gas exposure. The outer braid ensures physical protection and vibration resistance, while the welded nipples improve integration for welding or clamp-on systems.Alternate grades such as SS316 or carbon steel nipples are optional, based on environmental exposure or design needs.

Use Case & Integration Tips

In automotive, these pipes are commonly used in high-vibration zones or pre-silencer joints. For OEM use, nipple-ended hoses reduce secondary fixture costs and speed up assembly line production. For aftermarket installations, they provide a reliable weld-ready solution.

We have different types of exhaust flexible pipe, basic exhaust flexible pipe, exhaust flexible pipe with interlock, exhaust flexible pipe with innerbraid and exhaust flexible pipe with nipple, The exhaust pipe with nipple can help customers better match the use scenario and install quickly. In addition, we support the customization of products, including trademark lettering and packaging customization, as long as you ask questions, we will solve the problem for you.

Technical Specs Table

| Parameter | Specification |

|---|---|

| Material | Stainless Steel 304 |

| Braid Type | Single Layer Outer Braid |

| Nipple Type | Round Welded End |

| Length | 100mm – 500mm (custom) |

| Diameter | 38mm – 76mm standard |

| MOQ | 50 pcs |

| Packaging | Pallet or Carton Bulk Supply |

FAQs

Q1: Can we use the nipple flex pipe for turbocharged engines?

Yes. It is suitable for high-pressure exhaust flow and offers improved vibration isolation.

Q2: Can nipple materials differ from the bellows?

Yes, but we recommend material consistency to avoid heat expansion mismatch and galvanic corrosion.

Q3: Is it possible to customize the cap type or weld seam?

Absolutely. We offer MIG/TIG welds, K1/K2 caps, and laser-engraved ends.

Q: Can I order a sample? Is the quality guaranteed?

A: Absolutely,we provide samples and various test reports,and we will regularly do quantitative exhaust pipe corrosion resistance,anti-torque and other testing experiments,packaging will also do manual screening,all of which is to ensure the quality of each exhaust pipe,even if the exhaust pipe out of the problem,we will return after sale,please rest assured purchase.

Q: Do you have any experience in large volume cooperation?

A: We have large-scale pipeline project cooperation in China,and our customers all over the world,shipments can be fully guaranteed,we also often participate in the international large auto parts machinery exhibition,so whether online or offline,whether production or after-sales,we have quite good experience.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS