China Leading Supplier of Flex Pipes and Clamps for Exhaust

-

YUEDING EXHAUST

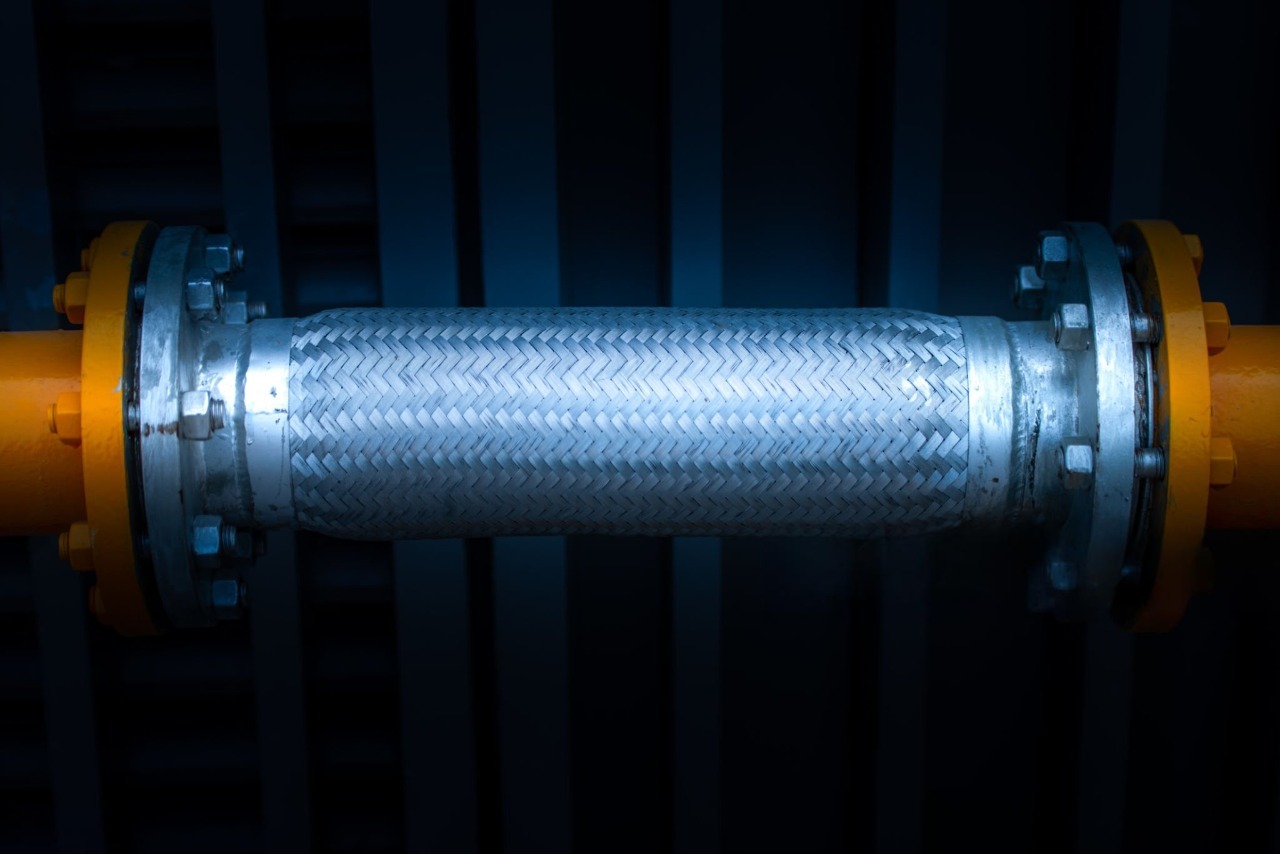

YDCT has been focusing on flexible pipe exhaust since 1992, continuously supplying high-performance components for automotive and industrial exhaust systems worldwide. With years of vertical integration and export experience, we are confident in meeting your needs for bulk purchasing and OEM/ODM customization of hose fastening and connection products, while maintaining sufficient supply and consistent delivery. - Reliable supply backed by a 20,000 sqm factory, automated production lines and sufficient inventory.

- Full in-house production, from forming and braiding to precision welding and surface treatment.

Custom Manufacturing Services for Global Distributors

Exhaust Solution Case Studies and Success Stories

Exhaust Connector Applications in Diverse Industrial Fields

Latest Industry Insights and Exhaust Product Updates

What Is Flex Pipe Stainless Steel And Its Applications in Exhaust System Design

Main function of stainless steel flex pipeIn real exhaust systems, stainless steel flex pipe is usually not for changing exhaust performance, but is used to deal with a long-existing but often ignored problem, that is the inevitable relative movement between the engine and the exhaust pipe.

Application Background of 4 inch diesel exhaust flex pipe and 5 inch exhaust flex pipe

4 inch and 5 inch stainless steel exhaust flex pipe are mainly used in diesel engines, trucks, and high-flow exhaust systems. With interlock liner and 304 stainless steel material, these flex pipes are suitable for OEM supply, replacement projects, and bulk purchasing.

Why 2 Inch And 2 1/2 Stainless Steel Flex Exhaust Pipe Are Common Sizes for OEM And Bulk Applications?

2 inch and 2 1/2 stainless steel flex exhaust pipe are widely used in OEM and bulk supply projects. From front-section small engines to mid-section long vehicles, these standard sizes ensure installation stability, vibration absorption, and consistent performance for maintenance and large-scale supply.

Exhaust Flex Coupler Selection Guide: What Affects System Lifespan

An exhaust flex coupler is a small part, but it has a big job. Its price is low, but the labor cost to replace it is high. Choosing the right technical spec—rather than the cheapest price—prevents repeated repairs and extra downtime. When you treat the selection as a technical decision, you ensure the long-term health of the entire exhaust system.

What is a Flexi Pipe Exhaust?

Did you know that a small component in your car’s exhaust system could prevent costly damage? The flexi pipe exhaust plays a vital role in maintaining your vehicle’s performance. Without it, your exhaust system could suffer from cracks and leaks.

What Is Interlock Flex Pipe ?

Interlock flex pipes are not a mandatory choice for every exhaust system, but in scenarios with higher requirements for reliability and service life, they are often a more conservative and stable option.

How To Select Proper Specifications of Stainless Steel Exhaust Flex Pipe ?

In summary, choose exhaust flex pipe not only look diameter. 2.5 inch exhaust flex pipe and 4 inch flex pipe exhaust difference not only number. You need look material, bellows structure, braid, expansion joint, nipple, cap and install environment.

How To Choose Right Exhaust Pipe Connector? What You Should Know

Some connectors have built-in fixing, easy to install, while others do not, so you need to select proper fixing method according to pipe diameter, material and usage, for example clamps or welding. Wrong fastening can cause pipe loosen, leak, or noise, and make maintenance more difficult.

Braided Or Mesh Braid Exhaust Flex Pipe, Which One Is Right for Your Application ?

After understanding braided and mesh/thin braided flex pipes, then you will see they are not “better or worse,” they are just two designs for different conditions. Braided is balanced, durable, and stable under normal use.

Exhaust Bellows Vs Flex Pipe, What Are The Differences?

Whether you are choosing flexible components for vehicles, construction machinery, generator sets, or industrial exhaust systems, the key is not to judge which is “better” between bellows and flex pipe, but to understand which one truly suits your operating conditions.