How Often Should Bellows Be Replaced?

Views: 0 Author: Site Editor Publish Time: 09-25-2025 Origin: Site

Have you ever wondered how often exhaust bellows should be replaced? These crucial components play a vital role in your vehicle's exhaust system. Regular maintenance and timely replacement are essential for optimal performance.

In this post, you'll learn about the lifespan of exhaust bellows, factors affecting their durability, and when to replace them.

Understanding Exhaust Bellows

What Are Exhaust Bellows?

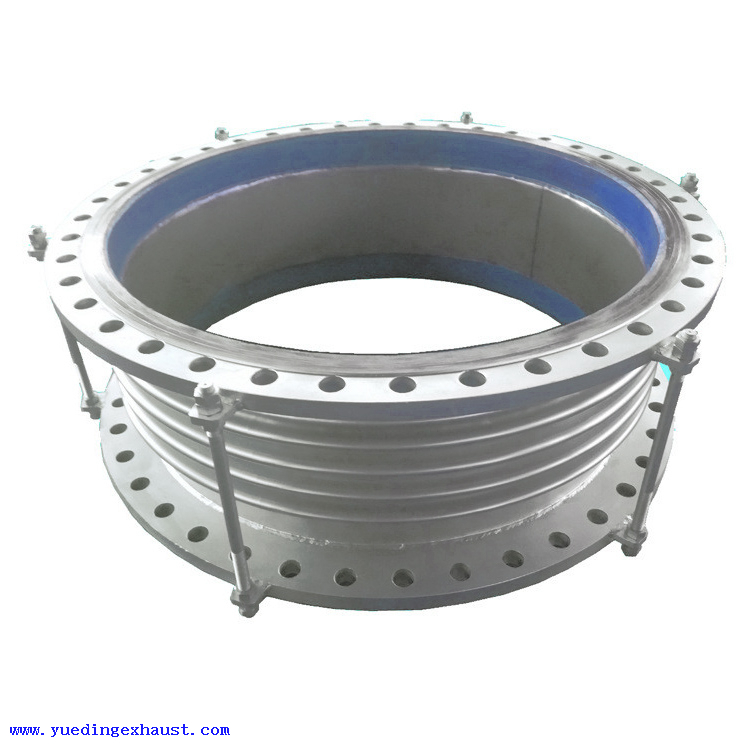

Exhaust bellows are flexible components in exhaust systems. They help absorb vibrations and accommodate movements caused by engine operation. Their main purpose is to prevent damage to the exhaust system and maintain a tight seal.

Types of Exhaust Bellows

1. Metal Bellows

a. Made from materials like stainless steel.

b. Highly durable and resistant to high temperatures.

c. Often used in heavy-duty applications.

2. Flexible Bellows

a. Typically made from rubber or elastomer.

b. More affordable but less durable than metal.

c. Common in passenger vehicles.

Type | Material | Durability | Cost |

Metal | Stainless Steel | High | Higher |

Flexible | Rubber/Elastomer | Moderate | Lower |

How Do Exhaust Bellows Work?

Exhaust bellows function as shock absorbers in the exhaust system. They allow for movement between the engine and the exhaust pipe. This flexibility helps reduce stress on other components, preventing premature wear.

Importance of Flexibility and Durability

● Flexibility: Allows the exhaust system to adapt to engine vibrations and movements. This is crucial for maintaining system integrity.

● Durability: Ensures that bellows can withstand harsh conditions, including extreme temperatures and corrosive elements. High-quality materials extend the lifespan, reducing replacement frequency.

In summary, understanding what exhaust bellows are and how they function is key to maintaining an efficient exhaust system. By recognizing their types and roles, you can make informed decisions about maintenance and replacement.

Factors Influencing the Replacement Frequency of Exhaust Bellows

Material Composition

Comparison of Metal and Flexible Bellows

When it comes to exhaust bellows, the material composition plays a crucial role in performance and lifespan. Let’s take a closer look at the two main types:

Metal Bellows

● Material: Typically made from stainless steel.

● Durability: Highly resistant to extreme temperatures and corrosive elements.

● Lifespan: Can last 5 to 10+ years with proper maintenance.

Flexible Bellows

● Material: Usually constructed from rubber or elastomer.

● Durability: More susceptible to wear and tear, especially in harsh environments.

● Lifespan: Generally lasts about 2 to 3 years, particularly under tough conditions.

Type | Material | Durability | Lifespan |

Metal | Stainless Steel | High | 5–10+ years |

Flexible | Rubber/Elastomer | Moderate | 2–3 years |

Lifespan Expectations Based on Material

1. Metal Bellows

a. Pros: Long-lasting, withstands high heat, and resists corrosion.

b. Cons: Higher initial cost, heavier than flexible options.

2. Flexible Bellows

a. Pros: Cost-effective and easier to install.

b. Cons: Shorter lifespan, can degrade quickly in extreme conditions.

Key Takeaways

● Metal bellows are ideal for long-term use and durability. They excel in demanding environments and can significantly reduce the need for frequent replacements.

● Flexible bellows are suitable for lighter applications but require more frequent checks and replacements. They may be a better fit for budget-conscious projects.

By understanding the differences in material composition, you can choose the right exhaust bellow for your needs. This choice impacts both performance and longevity, ensuring your exhaust system operates efficiently.

Operating Conditions

Impact of Temperature and Pressure on Lifespan

Operating conditions significantly affect the lifespan of exhaust bellows. High temperatures and pressure can lead to premature wear and tear. Let’s explore how these factors influence performance.

High-Temperature Environments

In high-temperature scenarios, such as turbocharged engines, exhaust bellows face extreme conditions. Here’s a breakdown:

● Turbocharged Engines: Can reach temperatures exceeding 500°C.

● Metal Bellows: Designed to handle temperatures above 800°C. This makes them ideal for high-performance applications.

● Flexible Bellows: Typically max out around 200°C, limiting their use in extreme environments.

Type | Max Temperature | Typical Use Cases |

Metal | 800°C+ | Turbocharged engines, racing |

Flexible | 200°C | Standard passenger vehicles |

Environmental Factors

Environmental conditions also play a crucial role in the lifespan of exhaust bellows. Different settings can lead to varying wear rates.

1. Marine Environments

a. Challenge: Saltwater exposure accelerates corrosion.

b. Recommendation: Annual inspections are crucial to catch any issues early. Regular maintenance helps extend lifespan.

2. Off-Road/Dusty Conditions

a. Challenge: Debris and dust can cause abrasion, leading to quicker deterioration.

b. Recommendation: Flexible bellows may need replacement every 1 to 2 years in these conditions. Regular checks are essential to ensure safety and performance.

Key Points to Remember

● Temperature: High heat can drastically shorten the lifespan of bellows, especially flexible types.

● Environment: Marine and off-road conditions require more frequent inspections and replacements due to increased wear.

By understanding how operating conditions impact exhaust bellows, you can make informed decisions about maintenance and replacement schedules. This proactive approach can save time and money in the long run.

Maintenance Practices

Importance of Regular Inspections

Regular inspections are crucial for maintaining the performance and longevity of exhaust bellows. By keeping a close eye on their condition, we can catch potential issues before they escalate. Here’s why this practice matters:

● Preventative Measure: Spotting problems early can save you from costly repairs down the line.

● Safety: Ensures the exhaust system operates efficiently, reducing risks of leaks or failures.

Visual Checks for Cracks, Leaks, or Ripple Deformation

Performing visual checks is a simple yet effective way to monitor the condition of exhaust bellows. Here’s what to look for:

● Cracks: Look for any visible fractures on the surface.

● Leaks: Check for signs of exhaust fumes escaping.

● Ripple Deformation: Ensure the bellows maintain their shape; any unusual ripples may indicate stress.

Yueding’s Precision-Formed Ripples

Yueding’s precision-formed ripples are designed to reduce stress points. This innovative design minimizes the risk of deformation, enhancing durability and performance.

Cleaning and Lubrication Requirements

Keeping exhaust bellows clean is essential for preventing corrosion and maintaining efficiency. Here’s how to manage this:

● Cleaning: Regularly remove soot and dirt buildup. This helps prevent corrosion and extends the lifespan.

● Lubrication:

○ Flexible Bellows: Require periodic lubrication to keep them functioning smoothly.

○ Metal Designs: Typically don’t need lubrication, making them lower maintenance.

Maintenance Task | Frequency | Notes |

Visual Inspections | Every 3–6 months | Check for cracks and leaks |

Cleaning | Monthly or as needed | Remove soot and dirt |

Lubrication (Flexible) | Every 6 months | Ensure smooth operation |

Signs of Wear and Tear to Look Out For

Being aware of the signs of wear and tear can help you act quickly. Here are some indicators:

● Unusual Noises: Hissing or rattling sounds may indicate a problem.

● Vibrations: Excessive vibrations during operation could signal a failing bellow.

● Visible Damage: Any cracks, bulges, or discoloration warrant immediate attention.

By adopting these maintenance practices, you can enhance the performance and lifespan of your exhaust bellows. Regular checks and cleaning are key to ensuring your exhaust system runs smoothly.

Industry Standards for Exhaust Bellow Replacement

Recommended Replacement Intervals

Knowing when to replace exhaust bellows is essential for maintaining system efficiency. Here are the recommended intervals:

● Metal Bellows:

○ Stationary Systems: Typically last about 7–10 years.

○ Mobile Use: Recommended replacement every 5–8 years due to increased wear from movement.

● Flexible Bellows:

○ Generally need replacement every 2–4 years, depending on operating conditions.

Interestingly, many competitors suggest a 2-year mandatory replacement for marine applications, even for metal bellows. This highlights the harsh conditions these components face in salty environments.

Type | Recommended Interval | Notes |

Metal (Stationary) | 7–10 years | Longer lifespan in stable settings |

Metal (Mobile) | 5–8 years | More wear due to movement |

Flexible | 2–4 years | Varies with environmental factors |

Marine (all types) | 2 years (mandatory) | High corrosion risk |

Competitor Benchmarks

Let’s take a look at what competitors are saying about replacement intervals. Many brands recommend shorter lifespans for exhaust bellows, particularly flexible types.

● Competitor Recommendations:Common guidelines suggest replacing flexible bellows every 2–3 years. This is often due to the use of low-grade materials that don’t withstand wear well.

Why Yueding’s Products May Offer Longer Lifespans

Yueding stands out in the market for several reasons:

● Welded Integrity: Our bellows are designed with superior welded integrity, which enhances durability.

● High-Quality Materials: We use premium materials that can endure over 10,000 thermal cycles. This significantly extends the lifespan compared to generic options.

Feature | Yueding Products | Competitors |

Welded Integrity | Superior | Varies; often lower quality |

Material Quality | High-grade | Often low-grade |

Thermal Cycle Endurance | 10,000+ cycles | Typically less than 5,000 cycles |

By understanding these industry standards and competitor benchmarks, you can make informed decisions about when to replace your exhaust bellows. This proactive approach helps maintain optimal performance and safety in your systems.

Signs That Exhaust Bellows Need Replacement

Visible Damage

One of the first indicators that your exhaust bellows may need replacement is visible damage. Here are the key signs to watch for:

● Cracks: Look closely for any cracks on the surface. Even small ones can lead to bigger issues.

● Rust: Corrosion indicates that moisture has compromised the material, which can weaken the bellows.

● Deformation: Any unusual bulges or changes in shape suggest stress and potential failure.

Signs of Exhaust Leaks

Exhaust leaks can be a serious problem. Here are some symptoms to keep an eye on:

● Noise: Unusual hissing or popping sounds may indicate a leak.

● Sulfur Odor: A strong sulfur smell can signal exhaust fumes escaping, which is dangerous.

Type of Damage | Signs to Look For | Potential Consequences |

Cracks | Visible fractures | Increased risk of leaks |

Rust | Corroded areas | Weakening of the material |

Deformation | Unusual shapes | Compromised performance |

Exhaust Leaks | Hissing sounds, odors | Health hazards and engine issues |

Performance Issues

Performance problems can also indicate that it’s time to replace your exhaust bellows. Here’s what to consider:

● Reduced Flexibility: If the bellows feel stiff or less flexible, they may not be able to absorb vibrations properly.

● Increased Stiffness: Over time, bellows can lose their elasticity. This stiffness can lead to further damage in the exhaust system.

Impact on Overall Engine Performance

When exhaust bellows fail, the entire engine can suffer. Here are some effects:

● Decreased Efficiency: A compromised exhaust system can reduce engine efficiency, leading to higher fuel consumption.

● Increased Emissions: Leaks can cause harmful emissions to escape, which is not only bad for the environment but also illegal in many areas.

Performance Indicator | Symptoms | Effects on Engine |

Flexibility | Stiffness | Poor vibration absorption |

Efficiency | Decreased power output | Higher fuel consumption |

Emissions | Increased pollutants | Environmental and legal issues |

By being aware of these signs, you can take action before a small issue turns into a major problem. Regular checks will help ensure your exhaust system remains in top shape.

Best Practices for Maintaining Exhaust Bellows

Regular Inspections

To keep your exhaust bellows in great condition, regular inspections are crucial. Here’s what you need to know:

● Inspection Frequency: Aim to inspect your bellows at least every six months. If you operate in harsh conditions, consider more frequent checks.

● What to Look For: Check for signs of wear, such as cracks, rust, and deformation. Pay attention to any unusual noises that may indicate leaks.

Importance of Professional Assessments

While DIY inspections are helpful, professional assessments are vital too. Trained technicians can identify issues you might miss, ensuring your system operates smoothly.

Inspection Aspect | Recommended Frequency | Notes |

Visual Checks | Every 6 months | More often in harsh environments |

Professional Review | Annually | Essential for thorough evaluations |

Key Signs to Observe | Cracks, rust, leaks | Early detection prevents failures |

Cleaning and Care

Keeping your exhaust bellows clean is essential for their longevity. Here are some best practices:

● Recommended Cleaning Methods: Use a soft brush and mild detergent to clean the bellows. Avoid harsh chemicals that may damage the material.

● Importance of Keeping Bellows Free from Soot and Dirt: Accumulated soot and dirt can cause corrosion and reduce flexibility. Regular cleaning helps maintain performance.

Cleaning Method | Recommended Tools | Frequency |

Soft Brush + Detergent | Non-abrasive materials | Every 3 months |

Inspection After Cleaning | Visual check | Immediately after cleaning |

Lubrication Needs

Lubrication is often necessary for flexible bellows, but it’s important to understand its role:

● Discussion on Lubrication for Flexible Bellows: Flexible bellows may require periodic lubrication to ensure smooth operation. Use appropriate lubricants recommended by the manufacturer.

● Why Yueding’s Metal Designs Eliminate Lubrication Needs: Yueding’s metal bellows are designed to function without lubrication. Their robust construction and materials ensure durability, reducing maintenance efforts.

Bellows Type | Lubrication Requirement | Benefits of Yueding’s Metal Designs |

Flexible Bellows | Yes | Requires regular maintenance |

Yueding Metal Bellows | No | Low maintenance, high durability |

By following these best practices, you can significantly extend the lifespan of your exhaust bellows and ensure optimal performance. Regular care and attention will pay off in the long run.

Case Studies and Real-World Examples

Success Stories with Yueding Exhaust Bellows

Yueding exhaust bellows have garnered numerous success stories from satisfied users. Here’s a closer look at what they have to say:

Testimonials from Users Regarding Longevity

Many users rave about the durability of Yueding bellows. Here are some highlights:

● User A: "I’ve had my Yueding bellows for over 8 years, and they’re still going strong!"

● User B: "Compared to my last set, these have outlasted them by years. I’m impressed!"

Comparison of Lifespan with Competitors

When comparing Yueding bellows to other brands, the difference is clear. Here’s a breakdown:

Brand | Average Lifespan | User Feedback |

Yueding | 8–10 years | Exceptional durability |

Competitor A | 5 years | Needs frequent replacement |

Competitor B | 4 years | Often reported issues |

Case Study: Freshwater Marine Users

A compelling case study involves freshwater marine users who have shared their experiences with Yueding bellows. Here’s what they found:

● Longevity: Users reported Yueding bellows lasting 8–10 years, significantly longer than competitors.

● Performance: Many noted improved performance and fewer maintenance issues compared to their previous bellows.

User Feedback Summary

● User C: "Switching to Yueding was the best decision. My previous brand only lasted 5 years."

● User D: "I’ve saved money on replacements and repairs since using Yueding bellows."

User Group | Yueding Lifespan | Competitor Lifespan |

Freshwater Marine | 8–10 years | 5 years |

Saltwater Marine | 7 years | 4 years |

By examining these real-world examples, it’s evident that choosing Yueding exhaust bellows can lead to significant savings and enhanced performance. Users consistently report satisfaction, making it a top choice in the market.

Conclusion

In summary, regular inspections and maintenance of exhaust bellows are vital.

Timely replacement enhances performance and ensures safety.

Users have reported significant longevity with Yueding bellows compared to competitors.

We encourage you to assess your exhaust bellows.

If needed, consult a professional for expert advice.

FAQ

Q: How can I tell if my exhaust bellows are failing?

A: Look for cracks, rust, or unusual noises. Regular inspections can help identify issues early.

Q: Are metal bellows really worth the investment?

A: Yes, metal bellows often last longer and require less maintenance compared to rubber options.

Q: What should I do if I notice a leak?

A: Address leaks immediately. Inspect the bellows and consult a professional for repair or replacement.

Q: Can I replace exhaust bellows myself?

A: While it’s possible, professional installation ensures proper fitting and performance.

Q: How do environmental factors affect exhaust bellow lifespan?

A: Harsh conditions like extreme temperatures and exposure to chemicals can shorten the lifespan of bellows.