MANUFACTURING CAPABILITIES

Factory Scale and Comprehensive Manufacturing Strength

As a manufacturer-based supplier of pipeline system products, Yueding's production base covers an area of more than 20,000 square meters, with workshop area exceeding 12,000 square meters. The overall layout is organized around the continuous production requirements of exhaust flexible bellows, metal bellows compensators, and supporting fasteners. Inside the factory, there are more than ten automatic and semi-automatic bellows production lines, covering core processes such as pipe cutting, bellows forming, braid assembly, and welding processing. The monthly output of bellows products can reach 350,000 pieces, which can meet the stability requirements of long-term and large-scale supply.

For fastener products, Yueding is equipped with forty to fifty types of automatic production lines, including German-style automated lines, heavy-duty automated lines, groove automated lines, and others. The automation rate of these production lines reaches 80%, with daily output of relevant clamp products ranging from 1.2 million to 1.5 million pieces. These lines mainly produce exhaust clamps, hose clamps, and related connectors, ensuring stable, large-scale production while maintaining structural consistency and assembly matching.

Currently, the total number of employees in the company exceeds 200, among which more than thirty are technical and R&D engineers, long-term involved in product structure design, material selection, and process improvement. The factory has an independent testing laboratory, carrying out tests on fatigue, pressure resistance, structural strength, sealing, and corrosion resistance for bellows and flexible connection products, used to verify product reliability and stability under different working conditions. Based on more than ten years of mature OEM/ODM service experience, Yueding can support customer drawing customization, small batch trial production, and process cooperation development, and has provided continuous and stable long-term supply services for many domestic and foreign customers in exhaust components and engineering fields.

production base area

workshop area

production lines

automation rate of production lines

Internal Production Cluster Advantages

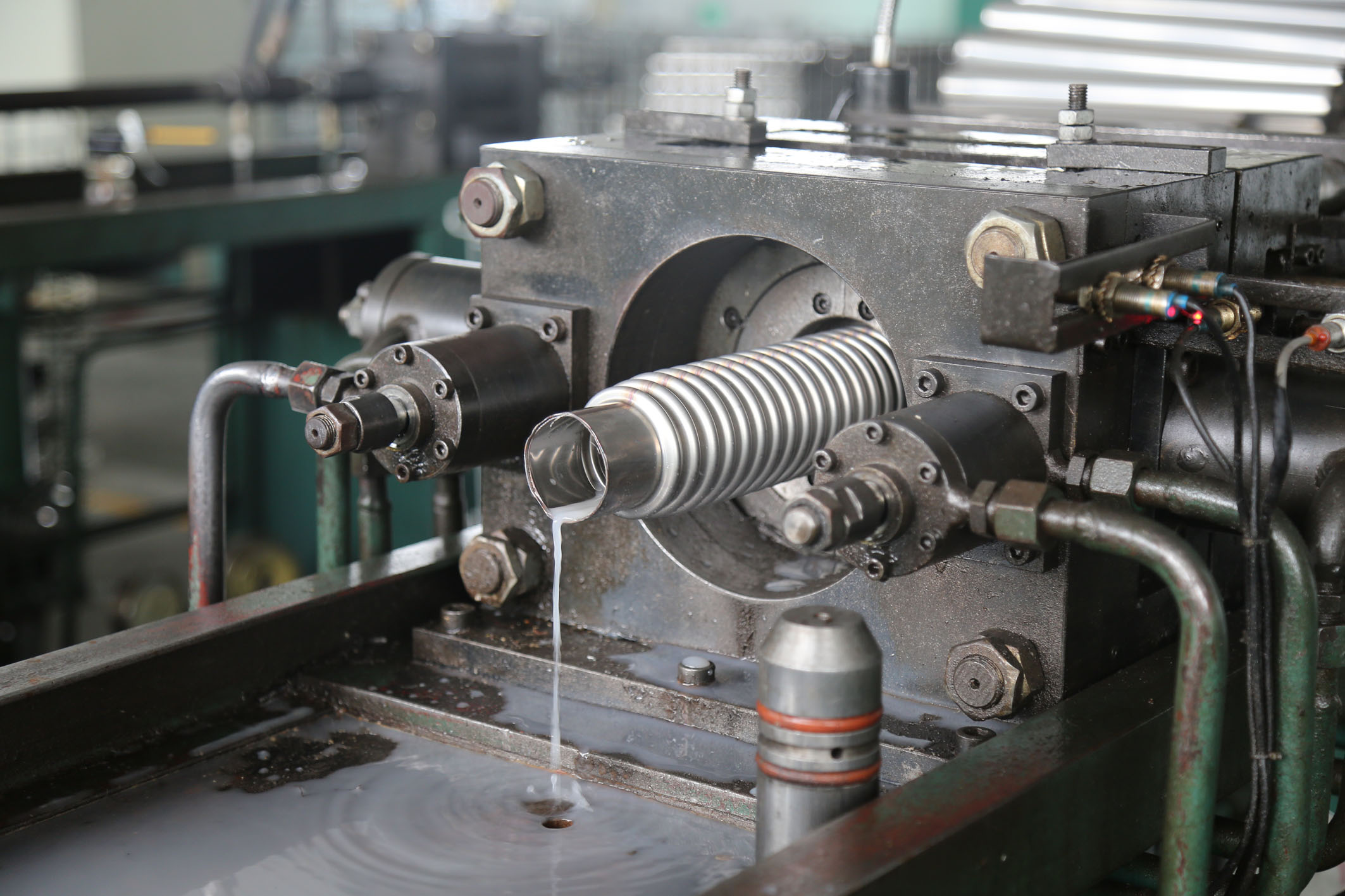

Yueding always insists on continuously introducing and improving related automation and semi-automation production equipment, this is beneficial to stable manufacturing of bellows parts and clamp products. In exhaust bellows production, we are equipped with semi-automatic hydraulic bellows forming and special CNC stamping machines, this makes stainless steel tube blanks keep consistent corrugation height and pitch during forming process, and then effectively improves controllability of product flexibility, fatigue resistance and structural stability. In clamp related production, we use highly integrated automated production line machines, which can put stamping, forming, welding and other key processes together and complete them in one equipment. Under condition of ensuring size consistency and welding stability, it also greatly improves single line output efficiency and reduces dependence on manual experience, so as to ensure our controllability on clamp quality and production rhythm in long-term batch supply.

About Our Team

Our frontline manufacturing team is the cornerstone of our Production Assurance. Comprising experienced technicians and certified operators.

Ensuring reproducible and sustainable manufacturing capability

Skilled operators trained to maintain zero-defect targets across automated lines

Dedicated full-time inspection team

Consistency & Reliability in Yueding Manufacturing

Full-Process Quality Control System

Yueding in long-term manufacturing process gradually established a process and quality control system with stability and controllability as core. Starting from raw material purchasing, company carries out specification checking and batch management for key raw materials such as stainless steel strip and tubes. Production process covers tube forming, bellows corrugation forming, braid assembly, welding processing, clamp forming and assembly, inspection and packing before delivery, each stage has clear process standards and quality control points.

Multi-Standard Quality Certification

Company has passed ISO9001 and ISO14001 quality management system certification, as well as IATF16949 certification and others. In actual production, company implements GB/T12777 “General Technical Conditions for Metal Bellows Expansion Joints”, EJMA (Expansion Joint Manufacturers Association standard) and other related technical requirements, and at same time establishes internal quality document system based on “Quality Manual”, “Quality System Procedure Compilation” and “Three-Level Documents”, to ensure all processes execute same standards under different batches and different production periods.

Multi-Level Quality Inspection Mode

In order to ensure traceability and stability of product quality, company sets independent full-time inspection team, and carries out inspection for key processes and finished products through combination of self-inspection, mutual inspection and special inspection, making quality control not rely on single personnel experience, but become a reproducible and sustainable manufacturing capability.

Full-Life-Cycle Technical Services

On this basis, Yueding pays attention to matching between process and actual application working conditions. According to customer requirements, company can provide complete technical documents and inspection reports, and provide technical support in product selection, pipeline design, installation and maintenance. Products under normal working conditions enjoy clear quality guarantee period. For quality problems occurring during use, company responds and handles according to process; for repairable products beyond warranty, company continues to provide technical support and spare parts service, to ensure products maintain reliable operation during entire service life.

OEM/ODM

During long-term manufacturing practice, Yueding has gradually established a relatively mature OEM/ODM service capability, and operates it as part of the daily production system rather than as a separate “custom project.” Relying on years of structural experience in metal bellows, exhaust flexible connectors, and related clamp products, the company can, based on customer-provided drawings, samples, or operating conditions, participate in preliminary discussions on product structure confirmation, material selection, process feasibility evaluation, and batch stability. For exhaust flex pipes, bellows compensators, and related fasteners, Yueding not only has the capability to produce according to drawings, but can also propose executable manufacturing suggestions on corrugation structure, braid type, welding scheme, and connection form based on an understanding of the operating environment and assembly conditions.

In actual OEM/ODM cooperation, the company supports a step-by-step approach from small trial production to stable mass production. Through sample verification, process confirmation, and accumulation of process data, the risks for customers during new product introduction are reduced. A relatively complete internal process documentation system, stable automated and semi-automated equipment configuration, and independent testing and inspection capabilities ensure that customized products maintain consistent performance across different batches and delivery cycles. For this reason, Yueding has provided long-term OEM/ODM support for many domestic and overseas automotive component, industrial equipment, and engineering customers, covering product development, mass supply, and subsequent iteration stages. The company values this continuous collaborative relationship more than one-time custom delivery.

Certified Performance Testing & Quality Validation

Testing Laboratory

Measurement Instrumentation

The relevant stainless steel raw materials undergo strict specification review and batch management upon entering the factory to confirm that chemical composition, thickness, and mechanical properties meet requirements. We mainly use a spectrometer to analyze chemical composition, and some materials are also checked with a two-dimensional measuring instrument for dimensional accuracy. This ensures that each batch of raw materials meets production standards in mechanical performance and structural consistency.

Regarding quality control in the production process, Yueding mainly sets key control points for forming, stamping, welding, and other processes, combined with regular inspections to ensure that stamping shape, welding strength, and crimping torque are all within the design range. We also pay great attention to the quality inspection process of finished products. For related clamps, we use Atlas torque wrenches to test clamping torque, cupping testing machines to test tear resistance, salt spray testing machines for corrosion resistance, and air tightness testing instruments to check sealing after installation, etc. For bellows, the focus is on testing corrugation stiffness, flexibility, pressure resistance, and fatigue performance, and salt spray tests and chemical composition analysis are carried out if necessary to confirm corrosion resistance and high-temperature performance.

The relevant stainless steel raw materials undergo strict specification review and batch management upon entering the factory to confirm that chemical composition, thickness, and mechanical properties meet requirements. We mainly use a spectrometer to analyze chemical composition, and some materials are also checked with a two-dimensional measuring instrument for dimensional accuracy. This ensures that each batch of raw materials meets production standards in mechanical performance and structural consistency.

Regarding quality control in the production process, Yueding mainly sets key control points for forming, stamping, welding, and other processes, combined with regular inspections to ensure that stamping shape, welding strength, and crimping torque are all within the design range. We also pay great attention to the quality inspection process of finished products. For related clamps, we use Atlas torque wrenches to test clamping torque, cupping testing machines to test tear resistance, salt spray testing machines for corrosion resistance, and air tightness testing instruments to check sealing after installation, etc. For bellows, the focus is on testing corrugation stiffness, flexibility, pressure resistance, and fatigue performance, and salt spray tests and chemical composition analysis are carried out if necessary to confirm corrosion resistance and high-temperature performance.

Experience Built Around Real Applications

YDCT has been helping customers solve connection and vibration problems in exhaust, pipeline, and industrial systems.We understand that every project needs parts that fit right and perform reliably under pressure, heat, and movement.Our team has designed and produced flexible pipes, clamps, and corrugated metal hoses for automotive, construction, power, and marine applications.This experience allows us to deliver the right solutions without the long learning curve — ready to meet your industry’s needs.

Automotive

Every drive depends on the parts you don’t see. Our exhaust flex pipes and clamps help vehicles stay quiet, efficient, and reliable mile after mile.