Exhaust Flex Pipe

Welcome to Yueding Exhaust Solutions! We are a dedicated enterprise providing high-quality Exhaust Flex Pipe products, offering reliable one-stop custom flex pipe solutions and soft pipe wholesale services for automotive and industrial exhaust systems. Free Samples Available for Bulk Orders!

What is the Stainless Steel Flex Pipe Exhaust ?

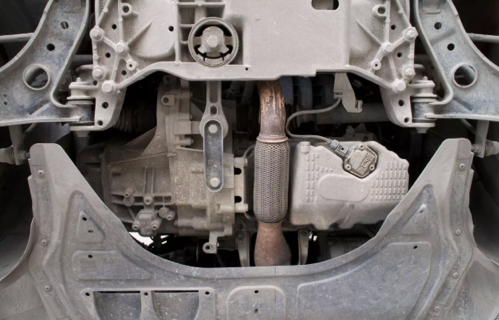

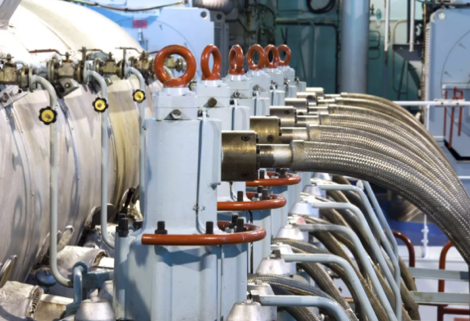

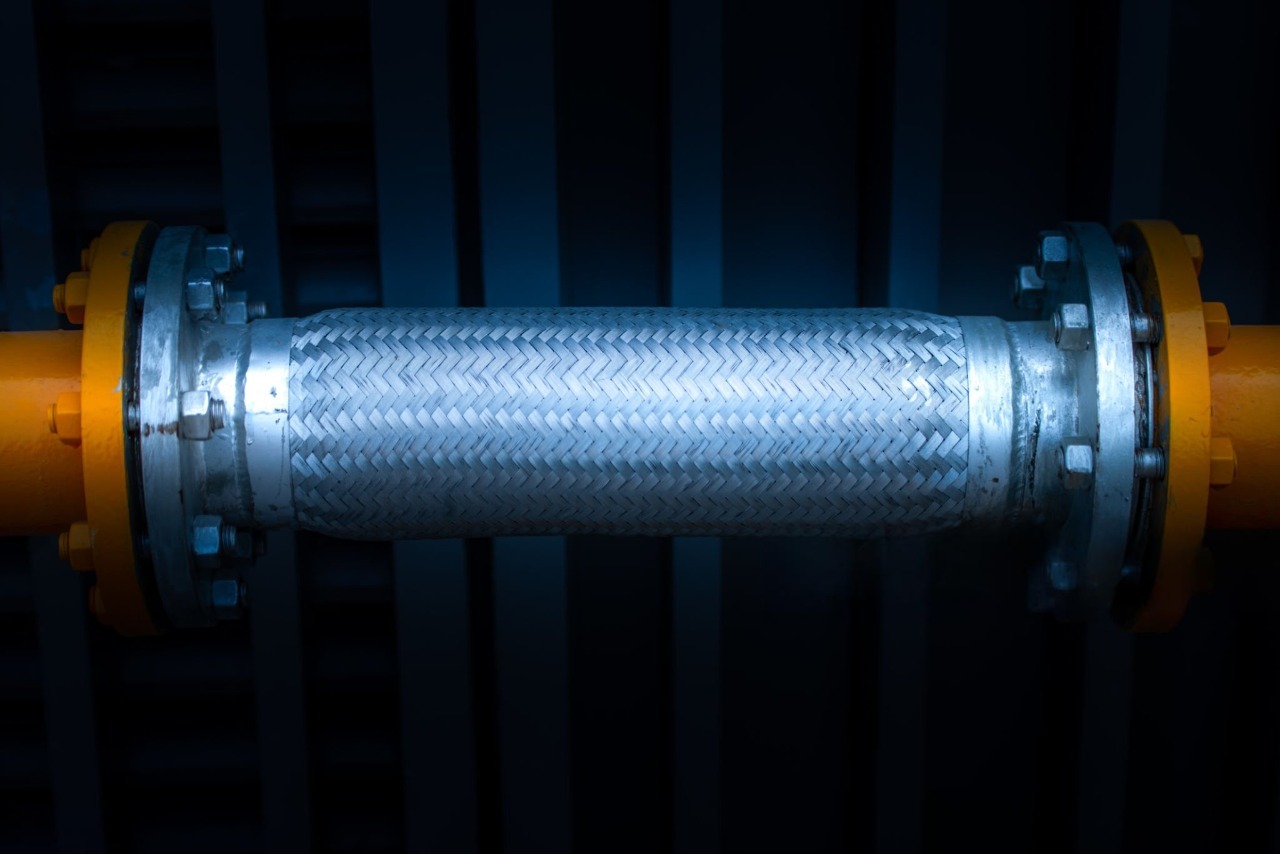

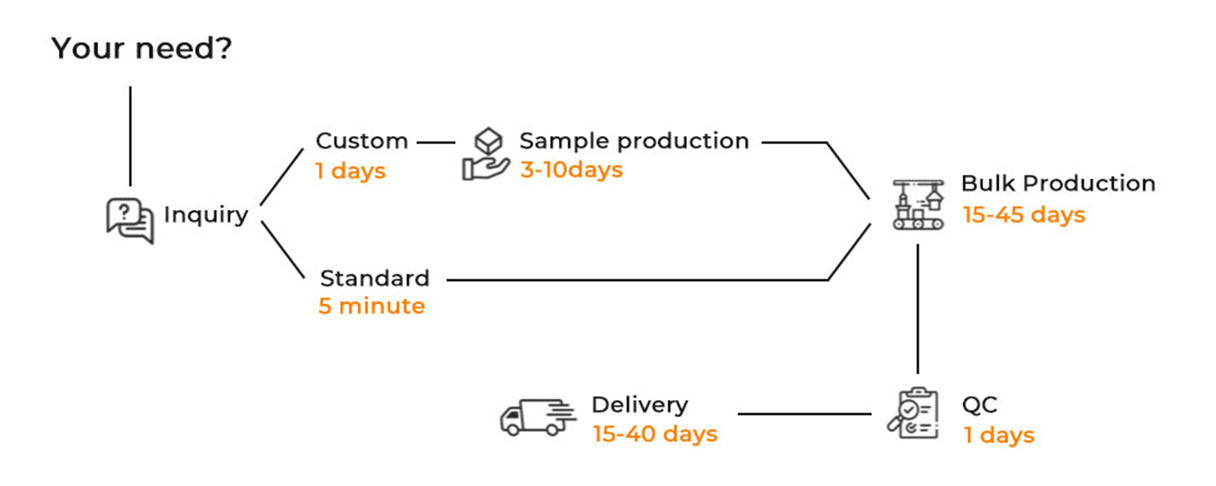

Exhaust flexible pipe is a key component in automotive and industrial exhaust pipe connection systems, designed to absorb vibration, compensate thermal expansion, and reduce stress on other exhaust pipe components. We provide standard universal exhaust flexible pipe, as well as upgraded structures such as interlock liner, inner braided mesh liner, fine mesh braided outer, and extended welded pipe types. In addition, we also supply long interlock hoses, braided hoses, exhaust bellows, and exhaust pipe clamps such as V-band flange clamps and U-bolt clamps. These exhaust flexible pipe components can widely solve exhaust flexible connection issues for passenger vehicles, trucks, marine vessels, construction machinery, and various industrial pipelines.

Flex Joint Exhaust Pipe Product

Exhaust Flex Couplings of Various Structures

YDCT manufacture flexible stainless steel pipe with distinct inner liner designs to meet specific NVH (Noise, Vibration, and Harshness) requirements.

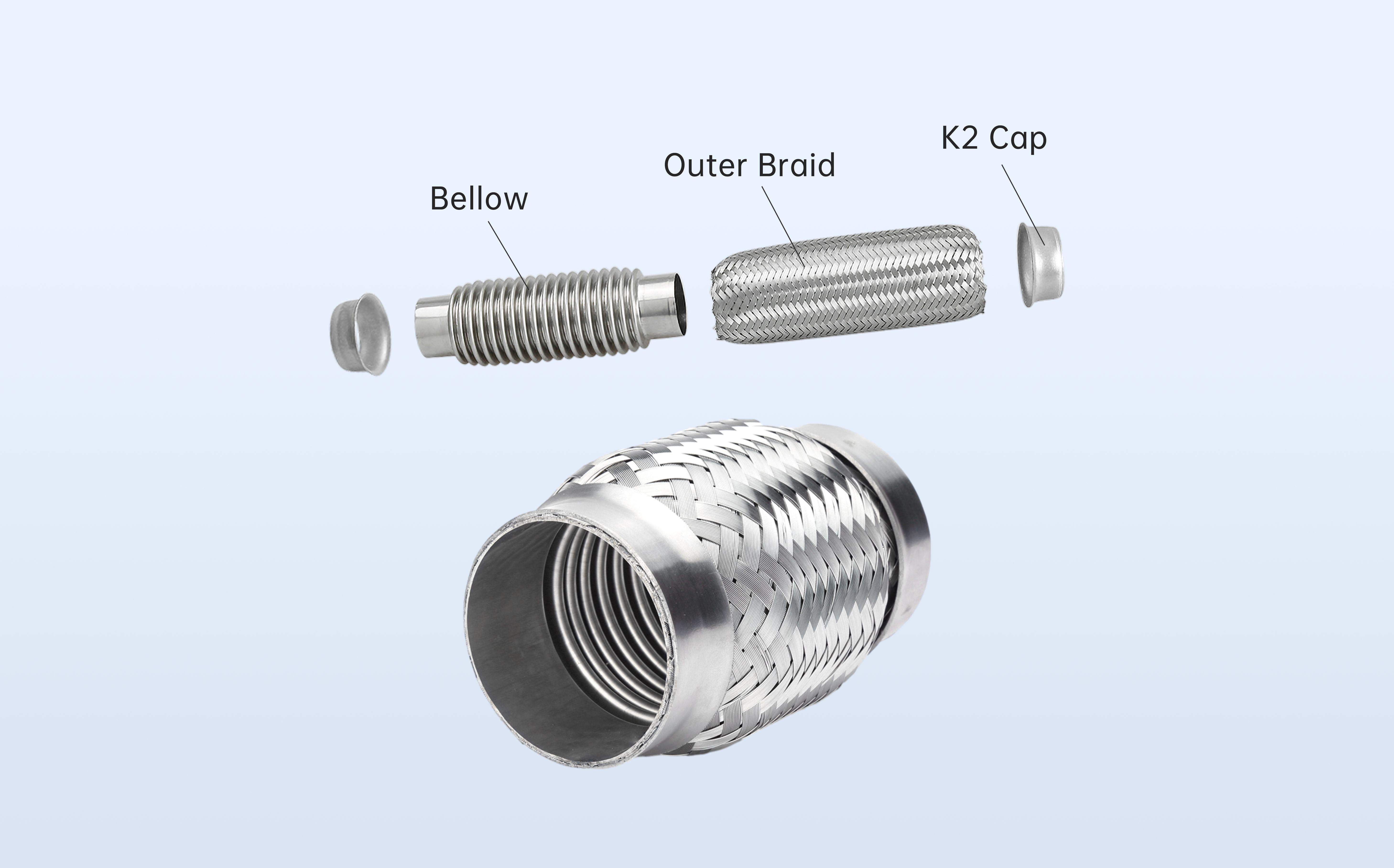

Base Construction (Standard Single Braid)

Structure: High-grade Bellows + Outer Braid + K2 Cap

Feature: This is the foundational design for vibration isolation. It features a robust K2 cap that secures the outer braid to the bellows.

Best For: Economic replacement solutions where basic vibration damping is required without the need for internal flow liners.

With Inner Braid (Noise Reduction)

Structure: Base Structure + Inner Braid

Feature: Engineered with a stainless steel inner wire braid. This additional layer significantly improves noise elimination functionality by smoothing exhaust gas flow and reducing turbulence.

Best For: Passenger vehicles requiring a quieter ride and protection for the bellows against exhaust pulses.

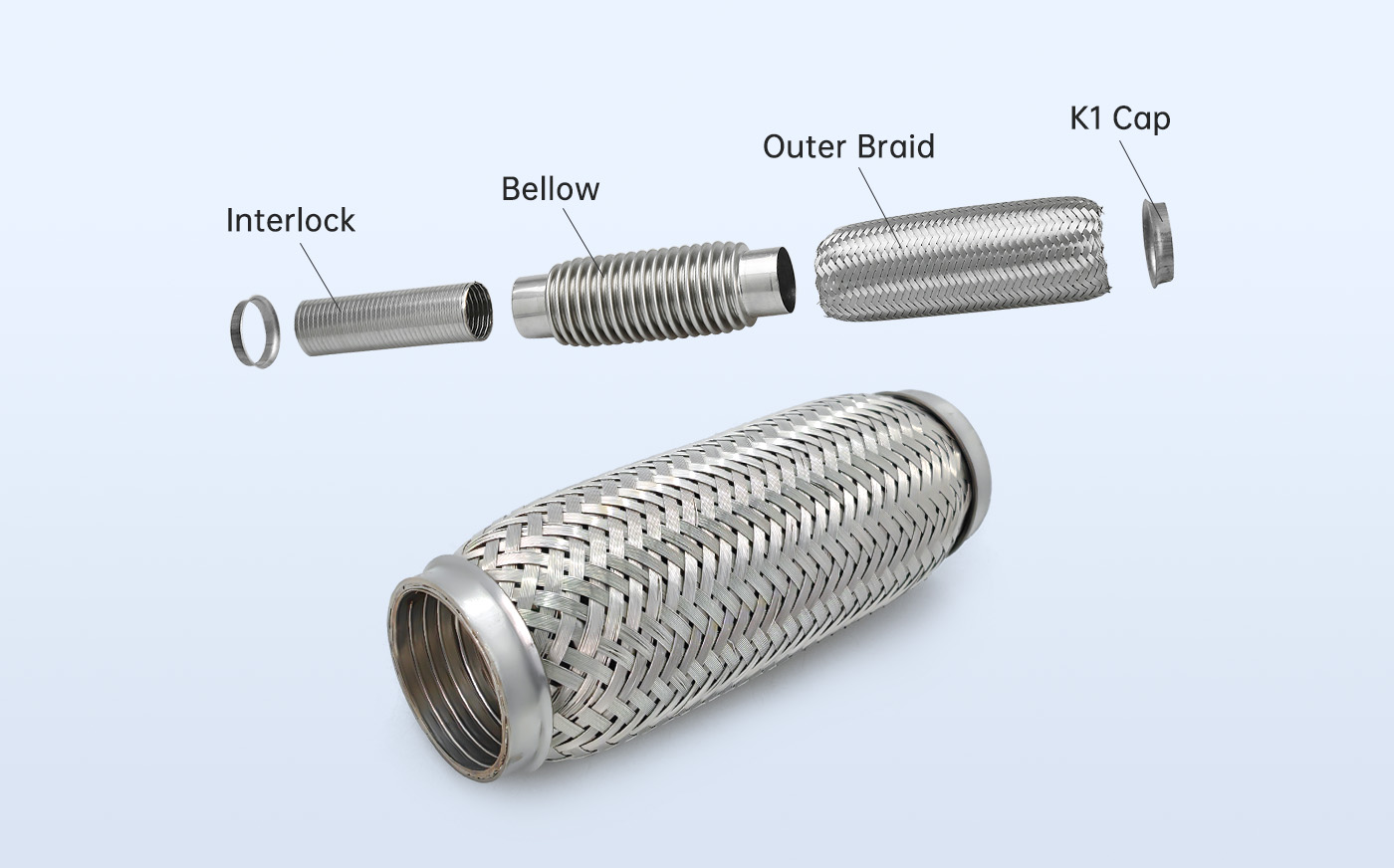

With Interlock (High-Temperature)

Structure: Base Structure + Interlock Liner + K1 Cap

Feature: This premium design utilizes a K1 cap and a flexible metal interlock hose. The interlock structure enhances resistance to higher temperatures and significantly increases the pipe's overall tensile strength.

Best For: High-performance engines, turbocharged applications, and commercial trucks where extending component lifespan is critical.

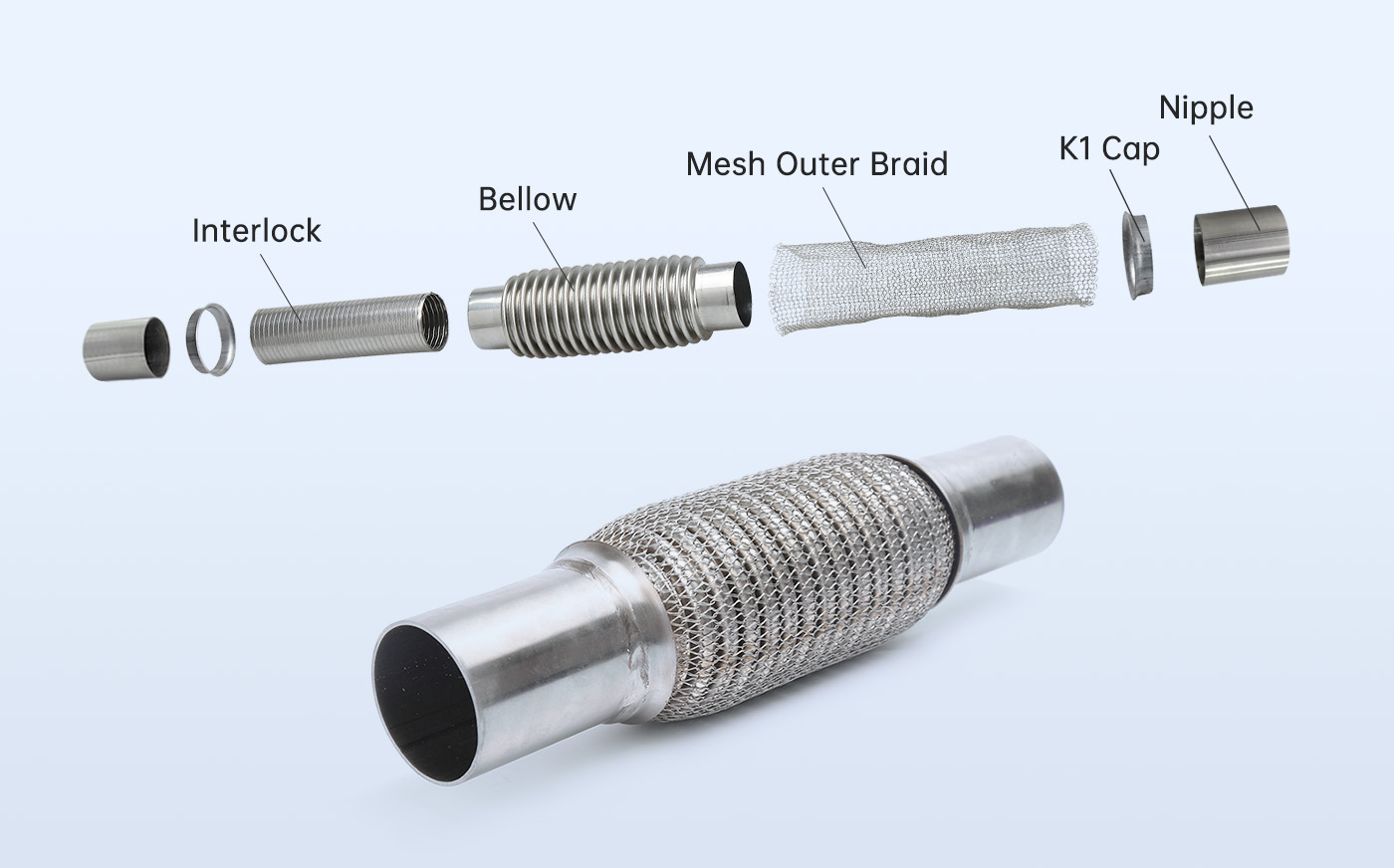

With Nipple (Enhanced Installation)

Structure: Available for all types + Extension Nipples.

Feature: Includes pre-welded nipples (extension tubes) on both ends. This configuration retains all the performance features of the base, inner braid, or interlock models but adds better welding capability.

Best For: Repair shops and assembly lines looking for a "ready-to-install" solution that simplifies the connection to existing exhaust piping.

Common Material Specifications for Automotive exhaust flexi

Automotive exhaust flexi are available in standard diameters ranging from 1 1/2 inch to 5 inch and larger, covering both passenger and high-flow exhaust systems. Across different sizes, material structure and forming methods remain consistent to maintain predictable flexibility and durability.

Material Selection (Steel Grades)

SS304 (Standard): The industry standard for exhaust bellows. Offers excellent corrosion resistance and high toughness.

SS316L (Premium): Features low carbon content and superior resistance to corrosion, ideal for marine environments or premium automotive applications.

SS321 (High Temp): A stabilized stainless steel capable of withstanding extreme temperatures (800°F - 1500°F), offering higher creep strength than SS304.

SS409 / Aluminized Steel: Commonly used for collars and extension pipes to match standard exhaust tubing cost-effectively.

Exhaust Flex Pipe Standard Size Reference Table

Choose from our wide selection of standard sizes or request a custom dimension. All part numbers listed below are IATF 16949 certified and ready for bulk ordering.

Part Number

Inlet Diameter (Inch)

Length (Inch)

Part Number

Inlet Diameter (Inch)

Length (Inch)

YD17504

1 3/4"

4"

YD22512

2 1/4"

12"

YD17506

1 3/4"

6"

YD25004

2 1/2"

4"

YD17508

1 3/4"

8"

YD25006

2 1/2"

6"

YD17509

1 3/4"

9"

YD25008

2 1/2"

8"

YD17510

1 3/4"

10"

YD25009

2 1/2"

9"

YD17511

1 3/4"

11"

YD25010

2 1/2"

10"

YD17512

1 3/4"

12"

YD25011

2 1/2"

11"

YD20004

2"

4"

YD30004

3"

4"

YD20006

2"

6"

YD30006

3"

6"

YD20008

2"

8"

YD30008

3"

8"

YD20009

2"

9"

YD30010

3"

10"

YD20010

2"

10"

YD30012

3"

12"

YD20011

2"

11"

YD35006

3.5"

6"

YD20012

2"

12"

YD35008

3.5"

8"

YD22504

2 1/4"

4"

YD35010

3.5"

10"

YD22506

2 1/4"

6"

YD35012

3.5"

12"

YD22508

2 1/4"

8"

YD40008

4"

8"

YD22509

2 1/4"

9"

YD40010

4"

10"

YD22510

2 1/4"

10"

YD40012

4"

12"

YD22511

2 1/4"

11"

Professional Flexible Exhaust Pipe Manufacturer

Why do global wholesalers and exhaust system manufacturers choose YDCT? Because we are not a trading company—we are a source factory controlling every step of production.

In-House Manufacturing

Our facility is equipped with advanced machinery, including hydraulic metallic hose making machines (DN32-DN350) and high-speed wire braiding machines (24-156 spindle). This ensures consistent wall thickness and braid tension.

Rigorous Quality Control

We adhere to IATF 16949 standards. Every batch undergoes: 100% Air Tightness Testing.Salt Spray Testing for corrosion resistance.Fatigue Lifecycle Analysis.

Global Reach

We successfully export to Russia, Australia, Brazil, the USA, and Europe, understanding the specific quality demands of each region.

OEM/ODM Capabilities

Need a custom logo or specific box design? We offer laser marking and custom packaging. Plus, our tooling team can develop custom molds in as little as 15 days.

Contact Us

Have questions or need a custom solution? Our team at Yueding Exhaust Solutions is ready to assist you with high-quality Exhaust Flex Pipe products, custom soft pipe requirements, and soft pipe wholesale inquiries. Get in touch today for expert advice and fast, reliable support.

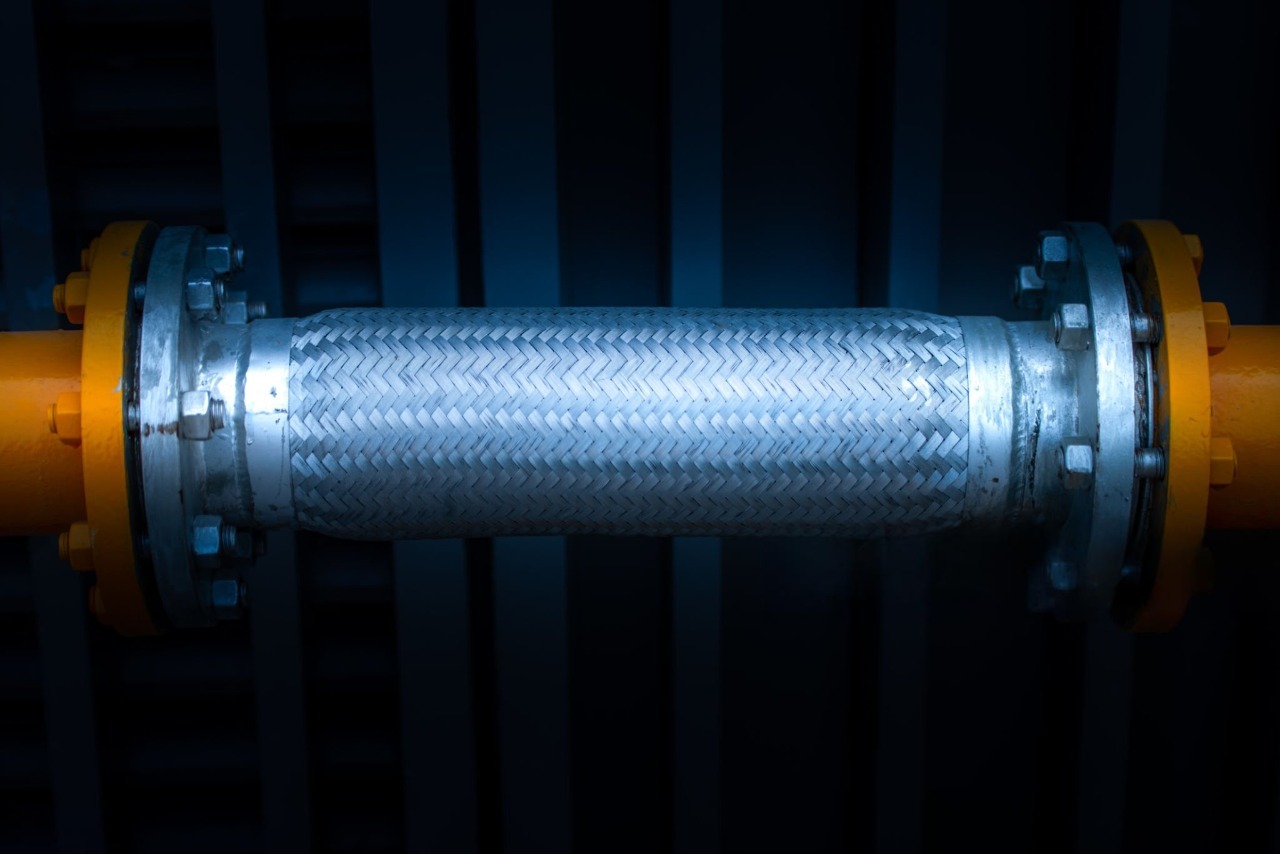

Applications of Flexible Exhaust Pipe Connector

Installation Tips

The "Natural Lie" Rule

Never install a flex pipe in a fully compressed or fully extended state. It should be installed in its "natural lie" (midway position) to allow for movement in both directions.

Correct Measurement

When cutting out an old pipe, measure the gap and add 3 inches (1.5" overlap per side) to determine the correct flex pipe length.

Welding vs. Clamping

While strap band clamps are suitable for Nipple-type pipes, MIG welding is recommended for standard flex pipes to ensure a hermetic seal and structural integrity.

Flexible Auto Exhaust Pipe Catalogue File Download

FAQs

Related Blogs

-

2 inch and 2 1/2 stainless steel flex exhaust pipe are widely used in OEM and bulk supply projects. From front-section small engines to mid-section long vehicles, these standard sizes ensure installation stability, vibration absorption, and consistent performance for maintenance and large-scale supply.

2 inch and 2 1/2 stainless steel flex exhaust pipe are widely used in OEM and bulk supply projects. From front-section small engines to mid-section long vehicles, these standard sizes ensure installation stability, vibration absorption, and consistent performance for maintenance and large-scale supply. -

An exhaust flex coupler is a small part, but it has a big job. Its price is low, but the labor cost to replace it is high. Choosing the right technical spec—rather than the cheapest price—prevents repeated repairs and extra downtime. When you treat the selection as a technical decision, you ensure the long-term health of the entire exhaust system.

An exhaust flex coupler is a small part, but it has a big job. Its price is low, but the labor cost to replace it is high. Choosing the right technical spec—rather than the cheapest price—prevents repeated repairs and extra downtime. When you treat the selection as a technical decision, you ensure the long-term health of the entire exhaust system.

Keep In Touch With Us

Partner with YDCT for factory-direct pricing, consistent quality, and reliable delivery. Whether you need standard replacements or custom OEM components, we have the capacity to meet your demands.

Mob:+86-13757770601

E-mail:mike@yuedingexhaust.com