Table of Contents

What Is an Exhaust Spherical Joint

Structural Components and Material Options of an Exhaust Spherical Joint

The Role of a Spherical Joint in the Exhaust System

Core Function and the Spring Compensation Mechanism

The Essential Difference Compared With a Flex Pipe

Why Many Automotive Manufacturers Choose This Structure

Common Specifications of Spherical Joints

How to Judge Whether You Need This Type of Connection

What is an exhaust spherical joint

You may have seen a special type of pipe connection product, which does not look like a simple flange connection and is also different from a flex pipe. The structure of this product usually consists of two pipe ends, a pair of flanges, a set of spring bolts, and a high-temperature sealing gasket. Its academic name is exhaust spherical joint, and in our factory we usually simply call it “ball head connection”.

Simply speaking, you can understand it as a kind of exhaust connection with a movable joint. It can achieve sealing, and it can also compensate the vibration and displacement of the pipe during working conditions. The reason why it is called spherical connection is because the two pipe ends can form a “ball-and-socket” structure that allows a small range of angle movement.

So when the engine vibrates and accelerates, and the exhaust pipe expands due to heat, the stress generated by the exhaust system will not all accumulate on the welds or flanges, which protects the entire pipe system, especially some expensive exhaust components, and extends their service life. This effect is actually similar to a flex pipe, but the two are still different, which will be mentioned below.

Also, you can see this kind of structural product in some mid-to-high-end models, such as Chrysler Jeep, BMW and Ford Focus original exhaust components. Some spherical joints have very long connecting tubes, and some use compact short flange joints. Actually, no matter which one it is, their core principle is the same. They are customized according to installation locations and pipe requirements. If our standard exhaust spherical joint products cannot meet your needs, you can also contact us for customized sizes and structures.

Structure and material of exhaust spherical joint

The core structure of the spherical connection is actually not complicated, and it is composed of several key functional components: the ball head pipe (the pipe end with a spherical bulge) and the ball socket pipe (the pipe end with the corresponding groove). The two cooperate to form a movable joint. In the middle of them is the very important high-temperature sealing gasket, and this type of gasket is usually a donut-shaped structure (Donut Gasket) made of composite materials such as graphite or refractory fiber. It is not metal, but it relies on flexibility to adapt and compensate for the slight movement of the metal pipe during vibration or thermal expansion and contraction, ensuring that the connection area always remains airtight. In addition, we will also use spring bolt assemblies and flanges. The flange is the connecting assembly, and the spring bolts continuously provide the pre-tightening force to press the gasket and at the same time absorb impact and maintain the sealing effect. Sometimes we also use flat washers to disperse the stress of the nut to protect the flange surface.

|  |

In terms of supply method, the spherical connections we ship from the factory are usually half-pre-assembled. The springs, bolts, and flanges have already been assembled to the standard pre-tightening force, and you can directly align the two pipes and install them after receiving them. Of course, some products will also be customized into repair kits for the convenience of aftermarket repair, making it easier to cut off the damaged original exhaust pipe and weld it directly. Whether it is a reducer pipe or other special installation method, these all support customization.

Talking about the material, the mainstream choice in our exhaust industry is to make a balance between cost and performance. For example, aluminized steel (a layer of aluminum coating on the outside of the steel material) is the cheapest and can cope with normal non-extreme climates; while 409 stainless steel, because of its good heat resistance and better corrosion resistance than aluminized steel, has become the first choice for many OE manufacturers’ front exhaust, balancing cost and lifespan. If the market environment where you are is harsh, such as coastal areas or you have very high quality requirements, we will directly recommend 304 stainless steel. Its corrosion resistance is extremely strong. Although the cost is higher, it can ensure the long-term anti-rust ability. We usually recommend that customers choose the appropriate material scheme based on the specific environment and quality requirements of their sales market.

Actual function of spherical joint in exhaust system

Core function and spring compensation mechanism

Every time the vehicle starts or accelerates, the exhaust pipes connected to it will shift and vibrate. So if your connections are all fixed welding or rigid flanges, the force will likely concentrate on one point, and over time it is likely to cause weld cracks or even pipe breakage.So the function of the spherical joint is to absorb these stresses that have nowhere to go. The spherical structure relies on the close fit between the metal sphere and the standard-angle socket, plus a high-temperature gasket, to ensure sealing even in high-pressure exhaust conditions, which is one aspect.

The key is the compensation function of the spring bolts. Whether the exhaust system is in a high-temperature or low-temperature state, the spring will continuously apply a stable force to ensure that the tightness and sealing of the connection will not loosen due to thermal expansion and contraction. It can be said that it solves the three major problems of displacement, stress and sealing under high heat and high vibration.

|  |

The essential difference with flex pipe

As mentioned earlier, flex pipes can also compensate displacement. So what is the difference?

First, the flex pipe mainly relies on its corrugated structure to absorb axial and radial vibration. It sacrifices the corrugated structure itself to protect the entire exhaust system, and we often see woven mesh breakage or bellows cracking. When this happens, a new flex pipe may need to be replaced, and to prevent damage to other exhaust parts.

The advantage of the spherical joint is that the maintenance cost is lower. It relies on spring bolts and gaskets to achieve sealing. If the gasket wears out, you just need to loosen the bolts and replace the gasket, and a single gasket is very cheap. But if a flex pipe fails, you may have to replace the entire assembly, and if it is welded, cutting and rewelding may be needed. Even though the flex pipe itself is not expensive, for regions with high labor cost, the spherical joint may be more suitable.

Of course, we must point out that the flex pipe being easy to fail mainly refers to regular single-layer exhaust bellows. As a professional exhaust flex pipe manufacturer, the upgraded products we supply, such as multi-layer bellows with inner braid, are designed to solve this pain point and also provide durable sealing and compensation. So if your customer is a consumer who pursues the highest durability and maintainability, we recommend the spherical joint; but if you are purchasing in bulk to cover many models and pursue cost-effective flexibility, our upgraded flex pipes are still more competitive in the market.

Why many automakers choose this structure

First is the structural durability. The spherical joint uses heavy flanges and strong spring designs, and the strength is much higher than other flexible connections in the exhaust system. It can reliably support part of the weight of the entire exhaust system, whether the pipeline is installed horizontally or vertically, and does not require the manufacturer to additionally design and install hangers. This design idea of reducing the number of parts directly improves the overall stability and assembly efficiency of the system, and also reduces manufacturing costs.

Second is the assembly tolerance. In large-scale automotive production lines, assembly accuracy cannot reach absolute perfection. The spherical connection allows the pipeline to have slight angular deviation, and relies on the ball-socket structure to achieve automatic alignment and sealing. This high tolerance is extremely important for the installation efficiency of the OEM production line.

Finally is the reliable guarantee of long-term performance. Because the spring continuously applies a stable pre-tightening force to the gasket, the spherical connection can still maintain its sealing and positioning effect after experiencing many years of high temperature, vibration, and road bumps. This effectively reduces the after-sales cost and reputation risks caused by exhaust leakage during the vehicle warranty period for the manufacturer.

Common specifications of spherical joints

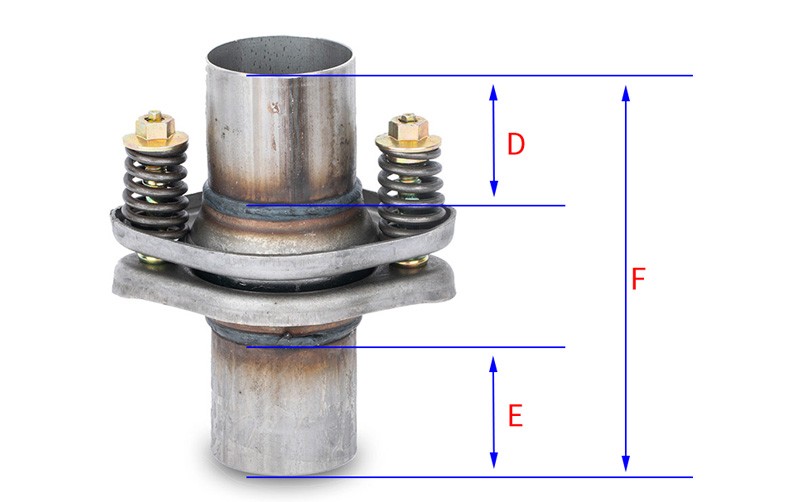

Below are common industry standard sizes, usually matched according to pipe diameter :

| Pipe Size | D (Flange OD) | E (Height) | F (Total Length) |

|---|---|---|---|

| 1.75″ | 2.5″ | 2.5″ | 7″ |

| 2″ | 2.5″ | 2.5″ | 7″ |

| 2.25″ | 2.5″ | 2.5″ | 7″ |

| 2.5″ | 2.5″ | 2.5″ | 7″ |

| 3″ | 2.5″ | 2.5″ | 7″ |

| 1.75″ | 2″ | 2″ | 6″ |

| 2″ | 2″ | 2″ | 6″ |

| 2.25″ | 2″ | 2″ | 6″ |

| 2.5″ | 2″ | 2″ | 6″ |

| 3″ | 2″ | 2″ | 6″ |

| 2″ | 1″ | 1″ | 4" |

Of course, if you have the relevant OE part numbers or are interested in specialized exhaust spherical flexible joints, or even individual components like exhaust flange gaskets, bolts, and springs, feel free to consult us. The exhaust parts industry is inherently multi-spec and mixed-use, and we handle custom solutions frequently, so you don't need to worry about that aspect.

How to judge whether you need this type of connection

When judging whether it is suitable to use an exhaust spherical joint, you can usually consider it from three angles: the vehicle structure, the usage environment, and the maintenance needs. For SUVs and pickup trucks with higher chassis and longer suspension travel, the mid-section exhaust will bear more obvious movement and impact during driving. If the vehicle originally uses a traditional flat-flange structure and has experienced situations such as slight leakage, exhaust noise, or increased vibration inside the cabin, then the spherical joint, with its more flexible angle compensation and longer-lasting sealing performance, often can solve these problems.

For wholesalers or repair shops in the aftermarket, whether this type of joint is needed depends more on the feedback from end customers and the local usage environment. If customers often complain about exhaust leakage, unstable sealing, or fatigue around welded areas, then introducing a spherical joint can reduce the occurrence of such situations. Because its spring structure can maintain a stable preload for a long time, technicians in many regions consider it a more worry-free solution, especially in areas with rough road conditions or large temperature differences.

In markets such as North America, Europe, and the Middle East, spherical joints have appeared more often in recent years, because their performance in long-term use is relatively stable, not easy to loosen due to thermal expansion and contraction, and can maintain sealing even when the pipe has slight misalignment. These characteristics make it a feasible choice when upgrading or repairing the exhaust system of many vehicles. If the market you are in has higher requirements for durability and after-sales stability of exhaust components, then this connection method may be a more reliable option.

If you already have samples on hand or are evaluating different types of exhaust connection structures, you are also welcome to discuss specific sizes and matching structures with us. We will provide more suitable versions according to the vehicle model, material, and usage conditions.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS