| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

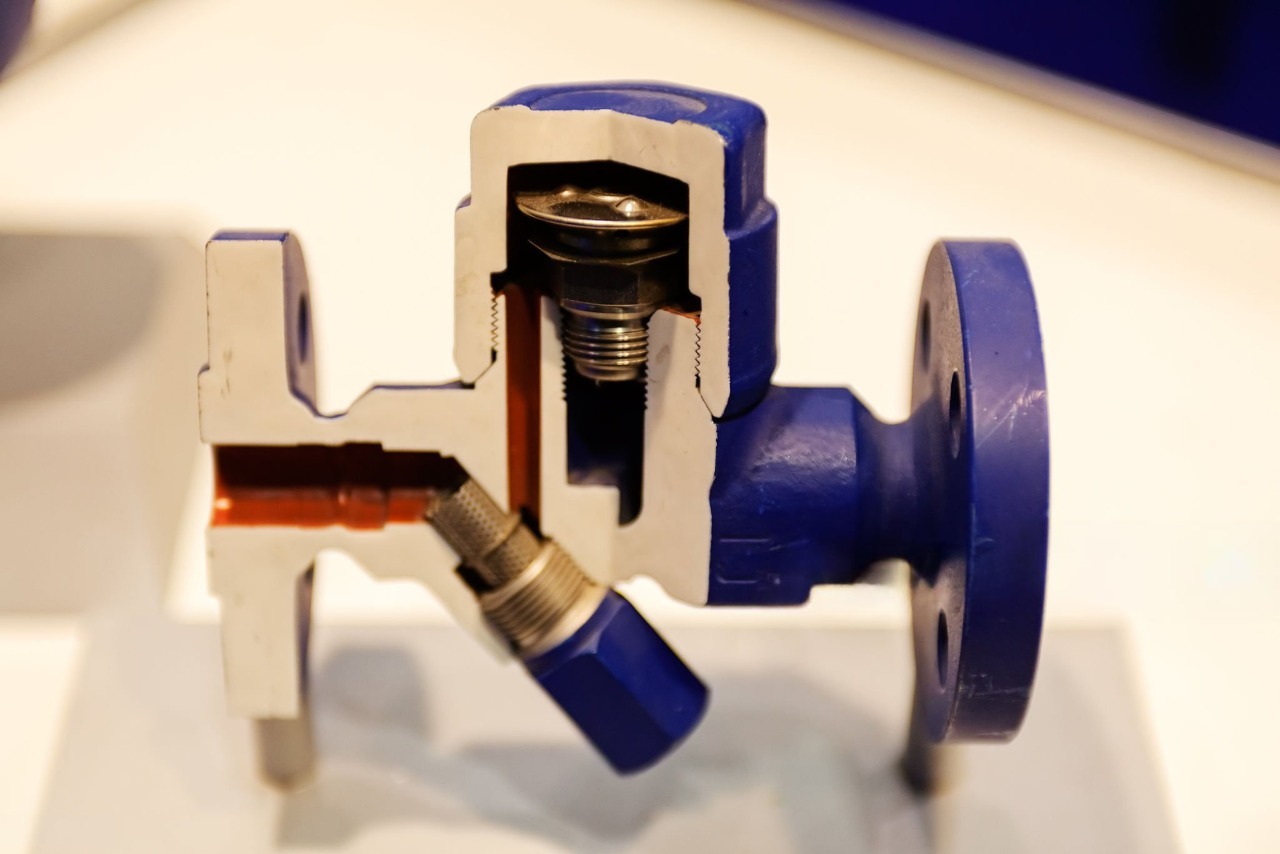

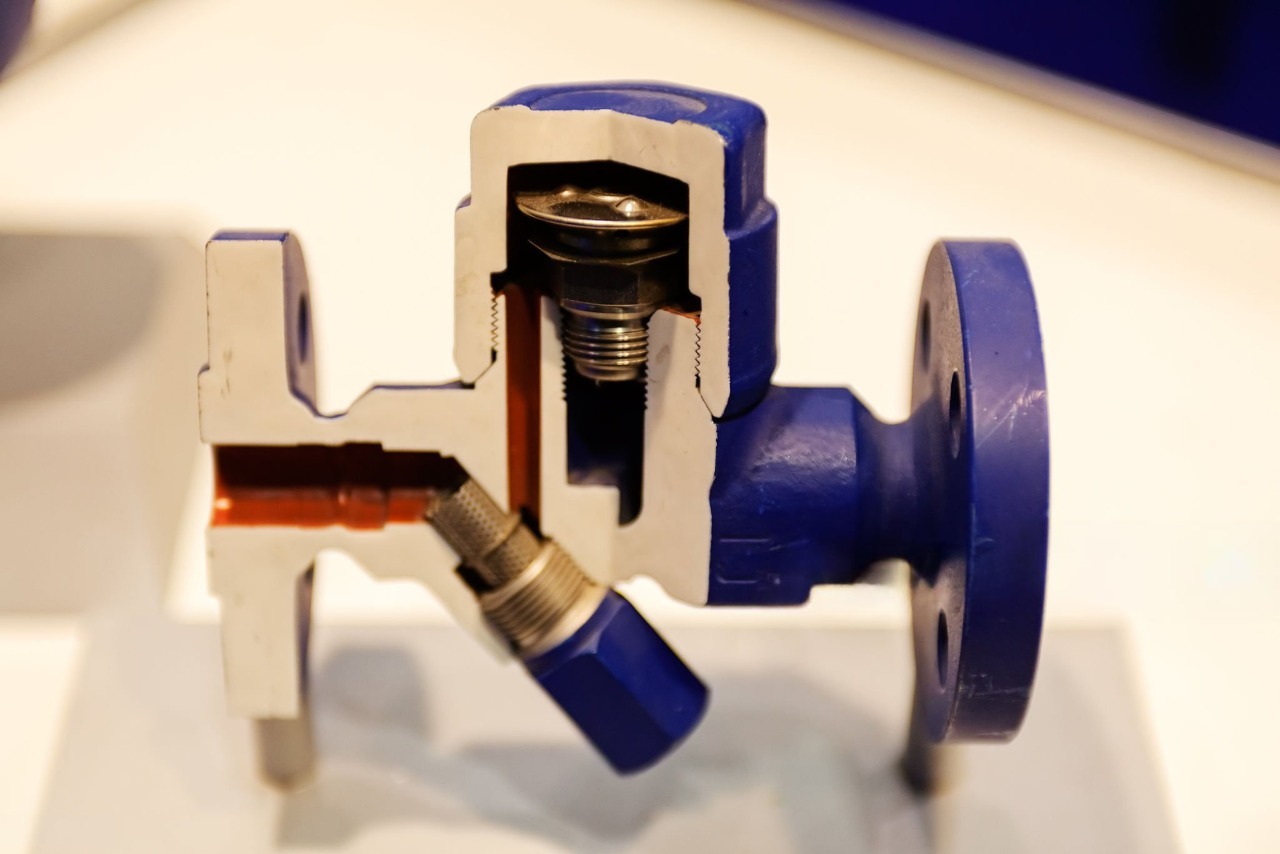

| These multiply precision bellows are used in pipe valves, testing instruments, and control systems where accuracy, flexibility, and leak-tight performance really matter. They work as small, flexible pressure seals or motion absorbers, helping to transmit, balance, or isolate pressure changes in delicate systems. Our factory has been producing metal bellows assemblies for years, focusing on reliable performance and practical cost control rather than just fancy specifications.Whether you need bellows for high-pressure valves, vacuum gauges, or precision test instruments, we can supply the right type and make sure it fits the function. | |||||||||

We keep a practical selection of precision bellows in stock for quick sampling and small production runs. Below are the common specifications you'll find available off-the-shelf or ready with short lead time:

| Item | Typical Range / Notes |

|---|---|

| Materials (stock) | Tin bronze (CuSn), Beryllium bronze (CuBe), Brass (CuZn), Stainless steel (SS304, SS316L) |

| Diameter | ~6–100 mm (standard stocked sizes; smaller or larger on request) |

| Length / Stroke | Matched to valve or instrument stroke requirements |

| Ply / Layers | 1–5 plies common (multi-ply improves fatigue life) |

| Manufacturing Types | Formed (hydroformed/roll-formed), Welded bellows, Edge-welded bellows |

| End fittings | Open ends, welded nipples, threaded ends, flanges (common sizes stocked) |

| Pressure / Temp (typical) | Low to medium pressure for bronze/brass; higher ratings with SS or special alloys; temp range depends on material |

| Testing | Basic leak check and dimensional inspection performed on stock items |

Notes and candid points:

our stocked tin-bronze and brass bellows are often used in instrument and valve OEM work where conductivity or moderate corrosion resistance is needed; beryllium bronze is kept for applications requiring higher strength and elasticity, but it's more controlled due to alloy handling; stainless steel stock is for higher-corrosion and temperature cases. Stock keeps lead time low, but if your spec is very unusual we’ll usually move to a short customization run.

We keep a practical selection of precision bellows in stock for quick sampling and small production runs. Below are the common specifications you'll find available off-the-shelf or ready with short lead time:

| Item | Typical Range / Notes |

|---|---|

| Materials (stock) | Tin bronze (CuSn), Beryllium bronze (CuBe), Brass (CuZn), Stainless steel (SS304, SS316L) |

| Diameter | ~6–100 mm (standard stocked sizes; smaller or larger on request) |

| Length / Stroke | Matched to valve or instrument stroke requirements |

| Ply / Layers | 1–5 plies common (multi-ply improves fatigue life) |

| Manufacturing Types | Formed (hydroformed/roll-formed), Welded bellows, Edge-welded bellows |

| End fittings | Open ends, welded nipples, threaded ends, flanges (common sizes stocked) |

| Pressure / Temp (typical) | Low to medium pressure for bronze/brass; higher ratings with SS or special alloys; temp range depends on material |

| Testing | Basic leak check and dimensional inspection performed on stock items |

Notes and candid points:

our stocked tin-bronze and brass bellows are often used in instrument and valve OEM work where conductivity or moderate corrosion resistance is needed; beryllium bronze is kept for applications requiring higher strength and elasticity, but it's more controlled due to alloy handling; stainless steel stock is for higher-corrosion and temperature cases. Stock keeps lead time low, but if your spec is very unusual we’ll usually move to a short customization run.

Tell us what you actually need: pressure rating, number of cycles, media, and installation details, and we'll propose the right build. Typical customization choices include:

1. Material selection

Tin Bronze (CuSn) , good wear resistance and general corrosion performance; commonly used in instrument and general industrial bellows.

Beryllium Bronze (CuBe) , high strength, good fatigue life, often chosen where non-magnetic or high-elasticity properties are required;

note: handling and control of beryllium alloys requires strict workplace safety and we'll discuss that with you.

Stainless Steel (SS304, SS316L.ect) , best for higher temperature, corrosive environments, wider pressure ranges; available in welded or multi-ply constructions.

High-elasticity alloys and other special materials, such as 1Cr18Ni9TiG, operate in the temperature range of 194℃~+400℃. They possess high bending fatigue strength and corrosion resistance, and exhibit good welding performance. They can be used as measuring, sealing, connecting, and compensating elements in corrosive media.

Brass (CuZn) , cost-effective for low- to medium-pressure instrument applications; easier machining and forming.

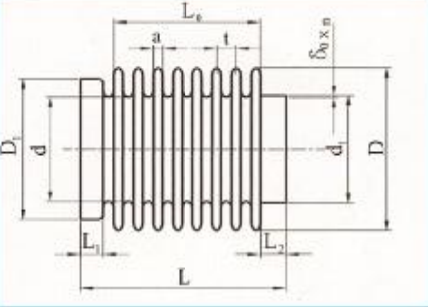

2. Ply / Wall & Geometry

Single vs multi-ply (2–5 plies typical). More plies → better fatigue life and flexibility control, but higher cost and slightly reduced internal volume.

Corrugation count and depth — affects stiffness and permissible movement. We’ll match corrugation design to your stroke and cycle life targets.

| D | Outer Diameter |

| d | Inner Diameter |

| δ₀ | Single-layer Wall Thickness of Bellows |

| t | Pitch |

| a | Wave Thickness |

| n | Number of Bellows Layers |

| L | Total Length |

| L₀ | Effective Length |

| L₁ | Inner Fitting End Length |

| L₂ | Outer Fitting End Length |

| D₁ | Inner Fitting Diameter |

| d₁ | Outer Fitting Diameter |

3. Manufacturing approach

Formed: suitable for certain sizes and thin-wall designs.

Welded bellows: precise, leak-tight, common for instrument and vacuum applications.

Edge-welded: used where full axial integrity and pressure capacity are required.

4. End connections & fittings

Welded nipples, threaded ends, flanges, or customer-specific adaptors. We can weld flanges or fit adapters to your drawing.

5. Testing & Certification

Helium leak test, pressure/fatigue cycle testing, material certificates (e.g., ASTM/ISO traces). If you need specific standards (AS9100, PED, ISO 9001) or test reports for qualification, we’ll plan that into the offer.

6.Packaging, labeling & traceability

Batch numbering, material traceability, EDI/PO references, OEM packaging — all available for volume orders.

Tell us what you actually need: pressure rating, number of cycles, media, and installation details, and we'll propose the right build. Typical customization choices include:

1. Material selection

Tin Bronze (CuSn) , good wear resistance and general corrosion performance; commonly used in instrument and general industrial bellows.

Beryllium Bronze (CuBe) , high strength, good fatigue life, often chosen where non-magnetic or high-elasticity properties are required;

note: handling and control of beryllium alloys requires strict workplace safety and we'll discuss that with you.

Stainless Steel (SS304, SS316L.ect) , best for higher temperature, corrosive environments, wider pressure ranges; available in welded or multi-ply constructions.

High-elasticity alloys and other special materials, such as 1Cr18Ni9TiG, operate in the temperature range of 194℃~+400℃. They possess high bending fatigue strength and corrosion resistance, and exhibit good welding performance. They can be used as measuring, sealing, connecting, and compensating elements in corrosive media.

Brass (CuZn) , cost-effective for low- to medium-pressure instrument applications; easier machining and forming.

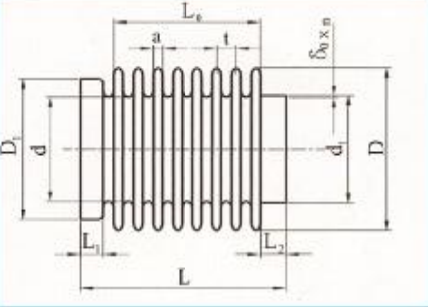

2. Ply / Wall & Geometry

Single vs multi-ply (2–5 plies typical). More plies → better fatigue life and flexibility control, but higher cost and slightly reduced internal volume.

Corrugation count and depth — affects stiffness and permissible movement. We’ll match corrugation design to your stroke and cycle life targets.

| D | Outer Diameter |

| d | Inner Diameter |

| δ₀ | Single-layer Wall Thickness of Bellows |

| t | Pitch |

| a | Wave Thickness |

| n | Number of Bellows Layers |

| L | Total Length |

| L₀ | Effective Length |

| L₁ | Inner Fitting End Length |

| L₂ | Outer Fitting End Length |

| D₁ | Inner Fitting Diameter |

| d₁ | Outer Fitting Diameter |

3. Manufacturing approach

Formed: suitable for certain sizes and thin-wall designs.

Welded bellows: precise, leak-tight, common for instrument and vacuum applications.

Edge-welded: used where full axial integrity and pressure capacity are required.

4. End connections & fittings

Welded nipples, threaded ends, flanges, or customer-specific adaptors. We can weld flanges or fit adapters to your drawing.

5. Testing & Certification

Helium leak test, pressure/fatigue cycle testing, material certificates (e.g., ASTM/ISO traces). If you need specific standards (AS9100, PED, ISO 9001) or test reports for qualification, we’ll plan that into the offer.

6.Packaging, labeling & traceability

Batch numbering, material traceability, EDI/PO references, OEM packaging — all available for volume orders.

These precision multiply bellows serve any application where sealed, repeatable motion or pressure isolation is needed. Typical sectors and uses include:

Valve & Flow Control,actuator compensation, pressure balancing in control valves for power, chemical and water treatment plants.

Test & Measurement Instruments,pressure gauges, calibration rigs, metering instruments where tight leak performance and repeatability matter.

Vacuum & Cryogenic Systems, welded bellows for leak-tight movement in vacuum chambers and instrumentation.

Energy & Chemical Equipment,compensating for thermal expansion, and protecting transmitters and sensors in corrosive media.

Rail & Heavy Machinery,components used in rolling stock systems and heavy-duty valves; note our existing collaboration history with CRRC and other industry partners.

OEM Precision Devices,medical instrument assemblies, industrial automation devices where small-size, high-precision bellows are integrated.

Some applications need very specific certifications or cleanliness (for example vacuum or medical). If that’s your case, please flag it early so we can confirm feasibility and required tests.

These precision multiply bellows serve any application where sealed, repeatable motion or pressure isolation is needed. Typical sectors and uses include:

Valve & Flow Control,actuator compensation, pressure balancing in control valves for power, chemical and water treatment plants.

Test & Measurement Instruments,pressure gauges, calibration rigs, metering instruments where tight leak performance and repeatability matter.

Vacuum & Cryogenic Systems, welded bellows for leak-tight movement in vacuum chambers and instrumentation.

Energy & Chemical Equipment,compensating for thermal expansion, and protecting transmitters and sensors in corrosive media.

Rail & Heavy Machinery,components used in rolling stock systems and heavy-duty valves; note our existing collaboration history with CRRC and other industry partners.

OEM Precision Devices,medical instrument assemblies, industrial automation devices where small-size, high-precision bellows are integrated.

Some applications need very specific certifications or cleanliness (for example vacuum or medical). If that’s your case, please flag it early so we can confirm feasibility and required tests.