Stainless Steel Exhaust Flex Pipe for Automotive Systems

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Application Scenarios:Automotive exhaust systems, industrial generators, heavy machinery, and off-road vehicles Manufacturing Processes:Hydroforming, precision welding, stainless steel wire braiding, and interlock sleeve forming Features:Excellent vibration isolation, thermal resistance, corrosion protection, and adaptability to complex exhaust routing Customization:Available in various lengths, diameters, braid styles (inner, outer, interlock), end cap types (K1/K2/nipple), and welding-ready interfaces | |||||||||

Product Introduction

YDCT's automotive exhaust flex pipe is designed to enhance the durability and efficiency of exhaust systems in commercial and industrial vehicles. Built with a flexible bellows core and wrapped in stainless steel braiding, this component plays a critical role in absorbing engine vibrations, compensating for thermal expansion, and extending the lifespan of exhaust systems under demanding working conditions.

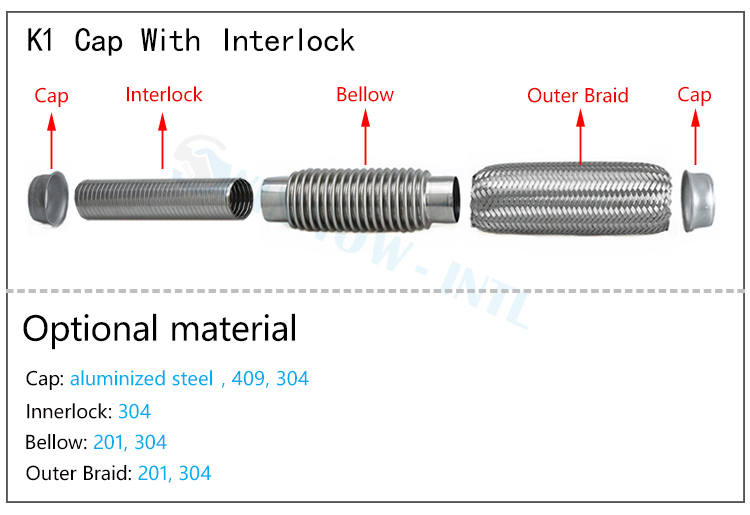

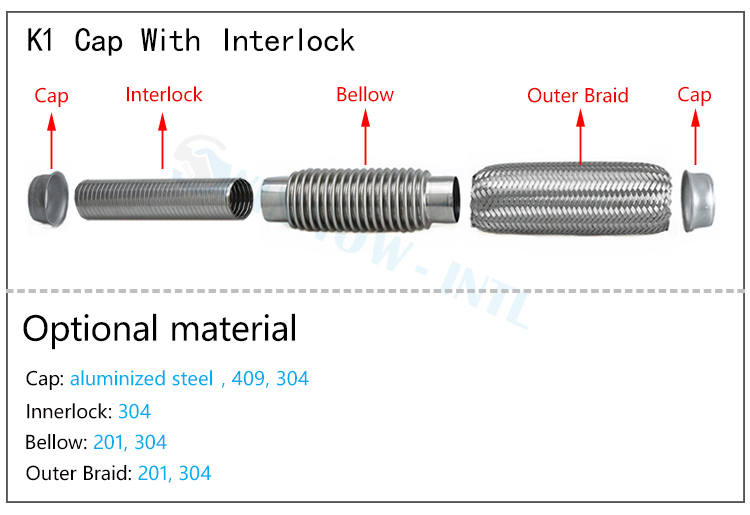

Our flex pipes are available in multiple construction types, including standard outer braid, inner braid for noise reduction, interlock structure for higher temperature resistance, and versions with welded nipples for enhanced weldability. Each variant is manufactured to meet the specific performance expectations of B2B buyers, including automotive OEMs, heavy machinery suppliers, and exhaust system fabricators.

Applications

This exhaust flex pipe is a key component in both light-duty and heavy-duty vehicle systems. It is widely used in:

Passenger cars and commercial trucks to reduce engine-induced vibration

Diesel generators and stationary engines for expansion joint compensation

Custom automotive tuning and performance exhaust systems

Agricultural and construction equipment to maintain exhaust line stability under load

Its design ensures that movements caused by engine motion, thermal fluctuations, or road vibrations are absorbed before they reach other exhaust components, reducing the risk of cracks or misalignment over time.

Features & Benefits

Each flex pipe is constructed using high-grade stainless steel, which offers excellent resistance to corrosion, especially in environments exposed to water, salt, or extreme heat. The braided design enhances the structural integrity of the pipe while allowing movement across multiple axes.

For specialized use cases, we offer:

Inner braid options: Enhance acoustic performance by reducing exhaust noise

Interlock design: Built to handle higher pressure and thermal loads with superior structural reinforcement

Welded nipple ends: Facilitates seamless integration with adjoining pipes during fabrication or replacement

All our designs prioritize long service life, installation flexibility, and ease of maintenance — key factors for B2B clients concerned with cost-effectiveness and system reliability.

Technical Specs Table

| Item | Description |

|---|---|

| Material | Stainless Steel (304/201/316 optional) |

| Length | Customizable (100mm–500mm or more) |

| Structure Options | Outer Braid / Inner Braid / Interlock |

| End Type | K1/K2 Cap, With or Without Nipple |

| Working Temperature | Up to 700°C depending on structure |

| Application | Automotive exhaust, vibration damping |

| Surface Finish | Bright annealed / Matte / Polished |

| Packaging | Individual shrink wrap or bulk box |

FAQs

Q1: What’s the difference between inner braid and interlock?

A: Inner braid reduces noise and turbulence, making it ideal for passenger vehicles. Interlock enhances heat resistance and structural strength, more suited for trucks or machinery.

Q2: Can you produce custom lengths or cap styles?

A: Yes, we provide full customization including bellows length, braid type, cap shape, and welding nipple requirements.

Q3: How is the welding quality controlled?

A: All welding is performed using precision TIG processes and 100% leak-tested to ensure reliability.

Q4: Can I request samples before bulk order?

A: Of course. Sample requests are welcome for compatibility verification.

Q5: What industries typically use your flex pipes?

A: We serve OEM and aftermarket suppliers across automotive, generator, agricultural, and construction machinery sectors.

Product Introduction

YDCT's automotive exhaust flex pipe is designed to enhance the durability and efficiency of exhaust systems in commercial and industrial vehicles. Built with a flexible bellows core and wrapped in stainless steel braiding, this component plays a critical role in absorbing engine vibrations, compensating for thermal expansion, and extending the lifespan of exhaust systems under demanding working conditions.

Our flex pipes are available in multiple construction types, including standard outer braid, inner braid for noise reduction, interlock structure for higher temperature resistance, and versions with welded nipples for enhanced weldability. Each variant is manufactured to meet the specific performance expectations of B2B buyers, including automotive OEMs, heavy machinery suppliers, and exhaust system fabricators.

Applications

This exhaust flex pipe is a key component in both light-duty and heavy-duty vehicle systems. It is widely used in:

Passenger cars and commercial trucks to reduce engine-induced vibration

Diesel generators and stationary engines for expansion joint compensation

Custom automotive tuning and performance exhaust systems

Agricultural and construction equipment to maintain exhaust line stability under load

Its design ensures that movements caused by engine motion, thermal fluctuations, or road vibrations are absorbed before they reach other exhaust components, reducing the risk of cracks or misalignment over time.

Features & Benefits

Each flex pipe is constructed using high-grade stainless steel, which offers excellent resistance to corrosion, especially in environments exposed to water, salt, or extreme heat. The braided design enhances the structural integrity of the pipe while allowing movement across multiple axes.

For specialized use cases, we offer:

Inner braid options: Enhance acoustic performance by reducing exhaust noise

Interlock design: Built to handle higher pressure and thermal loads with superior structural reinforcement

Welded nipple ends: Facilitates seamless integration with adjoining pipes during fabrication or replacement

All our designs prioritize long service life, installation flexibility, and ease of maintenance — key factors for B2B clients concerned with cost-effectiveness and system reliability.

Technical Specs Table

| Item | Description |

|---|---|

| Material | Stainless Steel (304/201/316 optional) |

| Length | Customizable (100mm–500mm or more) |

| Structure Options | Outer Braid / Inner Braid / Interlock |

| End Type | K1/K2 Cap, With or Without Nipple |

| Working Temperature | Up to 700°C depending on structure |

| Application | Automotive exhaust, vibration damping |

| Surface Finish | Bright annealed / Matte / Polished |

| Packaging | Individual shrink wrap or bulk box |

FAQs

Q1: What’s the difference between inner braid and interlock?

A: Inner braid reduces noise and turbulence, making it ideal for passenger vehicles. Interlock enhances heat resistance and structural strength, more suited for trucks or machinery.

Q2: Can you produce custom lengths or cap styles?

A: Yes, we provide full customization including bellows length, braid type, cap shape, and welding nipple requirements.

Q3: How is the welding quality controlled?

A: All welding is performed using precision TIG processes and 100% leak-tested to ensure reliability.

Q4: Can I request samples before bulk order?

A: Of course. Sample requests are welcome for compatibility verification.

Q5: What industries typically use your flex pipes?

A: We serve OEM and aftermarket suppliers across automotive, generator, agricultural, and construction machinery sectors.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS