Stainless Steel Exhaust Pipe Reducer Fitting

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Application Scenarios:Used to connect exhaust pipes of different diameters in automotive systems, industrial generators, and custom exhaust fabrication setups. Manufacturing Processes:Produced from stainless steel through cutting, CNC forming, and TIG welding to ensure dimensional accuracy and long-term resistance to heat and corrosion. Features:Supports high-temperature environments, precision fit for smooth airflow transition, corrosion-resistant, and compatible with various pipe connection methods. Customization:OEM customization available for pipe diameter, length, material grade, branding, and surface finish to meet project-specific or industry-standard requirements. | |||||||||

Product Introduction

The exhaust pipe adapter reducer is designed to connect exhaust components of different diameters, facilitating smooth transitions in piping systems. This component is widely used in automotive, truck, and industrial engine setups, ensuring that exhaust gases flow efficiently between mismatched pipe sizes. Made from corrosion-resistant stainless steel, it withstands thermal expansion and mechanical stress during long-term operation. Its role is critical in maintaining proper backpressure, reducing turbulence, and preventing exhaust leaks in custom or aftermarket installations.

Exhaust Adapter Reducer Applications

This adapter reducer is commonly used in automotive exhaust fabrication, aftermarket performance systems, industrial engine lines, and equipment requiring pipe transitions. In the automotive field, it enables the connection between exhaust pipes, mufflers, catalytic converters, and other components with varying diameters. It is also applied in diesel generators and industrial systems where exhaust gases need to be routed through custom piping. Fabricators and repair shops often rely on reducer fittings for quick adaptations during repairs or custom installations.

Technical Specifications of Exhaust Pipe Adapter Reducer

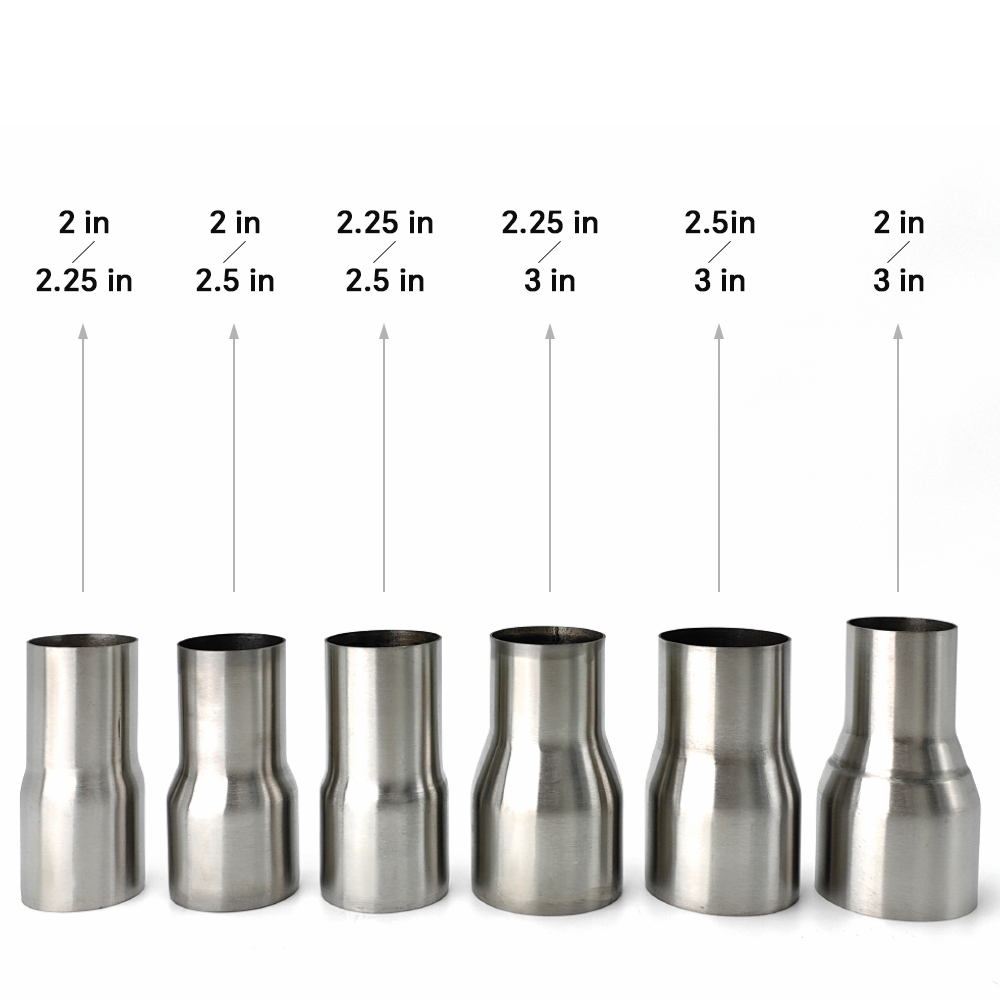

This adapter reducer is available in various size combinations such as 2" to 2.5", 2.5" to 3", and can be customized upon request. Wall thickness ranges between 1.2 mm and 2.0 mm depending on application demands. The material is typically SS304 or SS409, suitable for both automotive and light industrial exhaust systems. Connection types include slip-on or weld-on ends, and the length can be modified to suit installation constraints. Surface finishes include brushed, polished, or raw steel for welding.

| Size | Length (cm) | Width (cm) | Height (cm) | Volume (cm³) | Weight (g) |

|---|---|---|---|---|---|

| 51mm–57mm | 6.00 | 6.00 | 12.50 | 450.00 | 184 |

| 51mm–63mm | 6.50 | 6.50 | 13.00 | 549.25 | 200 |

| 51mm–76mm | 8.40 | 8.40 | 13.50 | 952.56 | 250 |

| 57mm–63mm | 7.00 | 7.00 | 13.30 | 651.70 | 225 |

| 57mm–76mm | 8.40 | 8.40 | 12.70 | 896.11 | 254 |

| 63mm–76mm | 8.30 | 8.30 | 12.90 | 888.68 | 254 |

Frequently Asked Questions About Exhaust Pipe Reducers

Q: How do I choose the correct adapter size?

Determine the outer diameter (OD) of the two pipes you intend to connect. The reducer should match those diameters exactly for a secure fit.

Q: Can this be used in high-performance exhaust setups?

Yes, it's suitable for high-temperature, high-flow systems and is often used in turbo applications and aftermarket exhaust builds.

Q: What materials are available?

Standard materials include SS304 and SS409. Other grades like SS316 can be offered on request for specialized applications.

Q: Is welding required for installation?

It depends on the design. Some reducers are slip-fit and can be secured with clamps, while others are intended for welding to ensure a permanent seal.

Q: Can you produce reducers with non-standard sizes or angles?

Yes, custom configurations are available based on drawing, sample, or technical specs provided by the buyer.

Product Introduction

The exhaust pipe adapter reducer is designed to connect exhaust components of different diameters, facilitating smooth transitions in piping systems. This component is widely used in automotive, truck, and industrial engine setups, ensuring that exhaust gases flow efficiently between mismatched pipe sizes. Made from corrosion-resistant stainless steel, it withstands thermal expansion and mechanical stress during long-term operation. Its role is critical in maintaining proper backpressure, reducing turbulence, and preventing exhaust leaks in custom or aftermarket installations.

Exhaust Adapter Reducer Applications

This adapter reducer is commonly used in automotive exhaust fabrication, aftermarket performance systems, industrial engine lines, and equipment requiring pipe transitions. In the automotive field, it enables the connection between exhaust pipes, mufflers, catalytic converters, and other components with varying diameters. It is also applied in diesel generators and industrial systems where exhaust gases need to be routed through custom piping. Fabricators and repair shops often rely on reducer fittings for quick adaptations during repairs or custom installations.

Technical Specifications of Exhaust Pipe Adapter Reducer

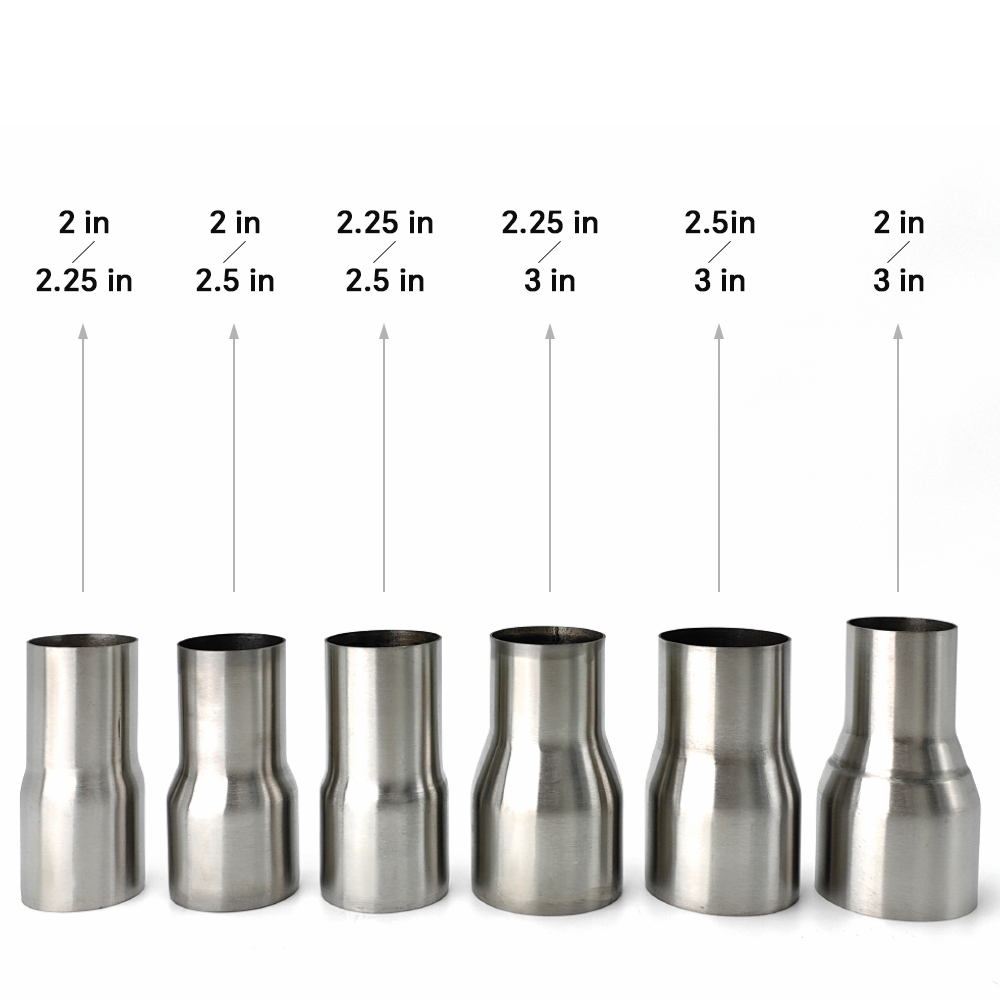

This adapter reducer is available in various size combinations such as 2" to 2.5", 2.5" to 3", and can be customized upon request. Wall thickness ranges between 1.2 mm and 2.0 mm depending on application demands. The material is typically SS304 or SS409, suitable for both automotive and light industrial exhaust systems. Connection types include slip-on or weld-on ends, and the length can be modified to suit installation constraints. Surface finishes include brushed, polished, or raw steel for welding.

| Size | Length (cm) | Width (cm) | Height (cm) | Volume (cm³) | Weight (g) |

|---|---|---|---|---|---|

| 51mm–57mm | 6.00 | 6.00 | 12.50 | 450.00 | 184 |

| 51mm–63mm | 6.50 | 6.50 | 13.00 | 549.25 | 200 |

| 51mm–76mm | 8.40 | 8.40 | 13.50 | 952.56 | 250 |

| 57mm–63mm | 7.00 | 7.00 | 13.30 | 651.70 | 225 |

| 57mm–76mm | 8.40 | 8.40 | 12.70 | 896.11 | 254 |

| 63mm–76mm | 8.30 | 8.30 | 12.90 | 888.68 | 254 |

Frequently Asked Questions About Exhaust Pipe Reducers

Q: How do I choose the correct adapter size?

Determine the outer diameter (OD) of the two pipes you intend to connect. The reducer should match those diameters exactly for a secure fit.

Q: Can this be used in high-performance exhaust setups?

Yes, it's suitable for high-temperature, high-flow systems and is often used in turbo applications and aftermarket exhaust builds.

Q: What materials are available?

Standard materials include SS304 and SS409. Other grades like SS316 can be offered on request for specialized applications.

Q: Is welding required for installation?

It depends on the design. Some reducers are slip-fit and can be secured with clamps, while others are intended for welding to ensure a permanent seal.

Q: Can you produce reducers with non-standard sizes or angles?

Yes, custom configurations are available based on drawing, sample, or technical specs provided by the buyer.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS