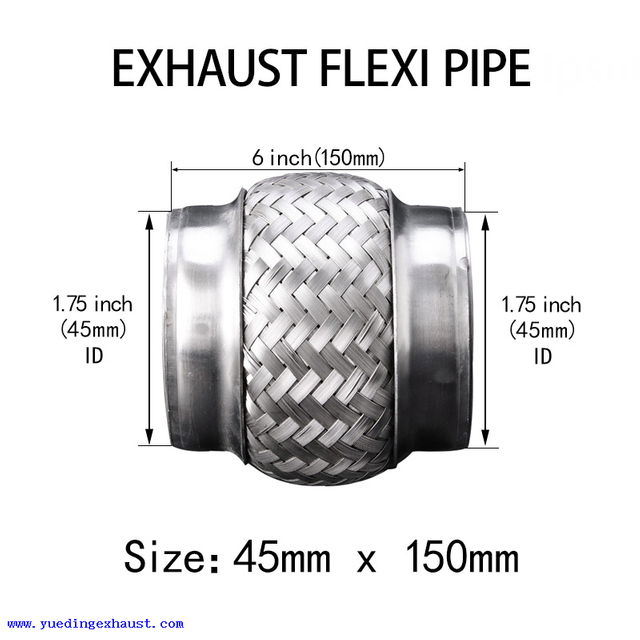

- We supply standard inner diameters from 1 3/4 inch to 4 inch and lengths from 4 inch to 12 inch. Larger sizes and custom dimensions are available on request.

- Our exhaust flex pipes are manufactured from stainless steel 201, 304, 409, and 316, with optional aluminized steel end fittings.

-

Yes. We provide OEM development based on drawings or samples, offer customized packaging, and maintain stock for aftermarket distributors.

-

Our factory is ISO certified, equipped with spectrometry and salt spray testing. Each batch undergoes torque and leak testing before shipment.

- We maintain a monthly capacity of 350,000 units and export globally with efficient logistics, ensuring reliable lead times for bulk and repeat orders.