Braided Or Mesh Braid Exhaust Flex Pipe, Which One Is Right for Your Application ?

Table of Contents

Braided and mesh/thin braided flex pipes

Understanding the overall structure of exhaust flex pipes

Core differences between the two outer braid structures: restriction, flexibility, and friction

Materials, process, and manufacturing

Why braided structures are more common

Questions you may want to ask

Summary

Braided and mesh/thin braided flex pipes

If you are encountering exhaust flex pipes for the first time, and see two products that look slightly different: one has a dense, fabric-like uniform surface, while the other is more sparsely braided with coarser patterns, you might suspect that the latter uses less material. Perhaps what concerns you is not just “they look different,” but more about why the same flexible pipe has two types of outer mesh structures, what the technical logic is, and whether this structural difference affects vehicle performance. From our long-term export experience with exhaust flex pipes, the outer mesh is not just a decorative layer; it directly affects the bellows’ range of movement, friction characteristics, vibration resistance, and even noise performance. Understanding this allows you to truly judge whether a flex pipe is suitable for your project.

| Braid exhaust flex pipe | Thin braid exhaust flex pipe | Mesh braid exhaust flex pipe |

Understanding the overall structure of exhaust flex pipes

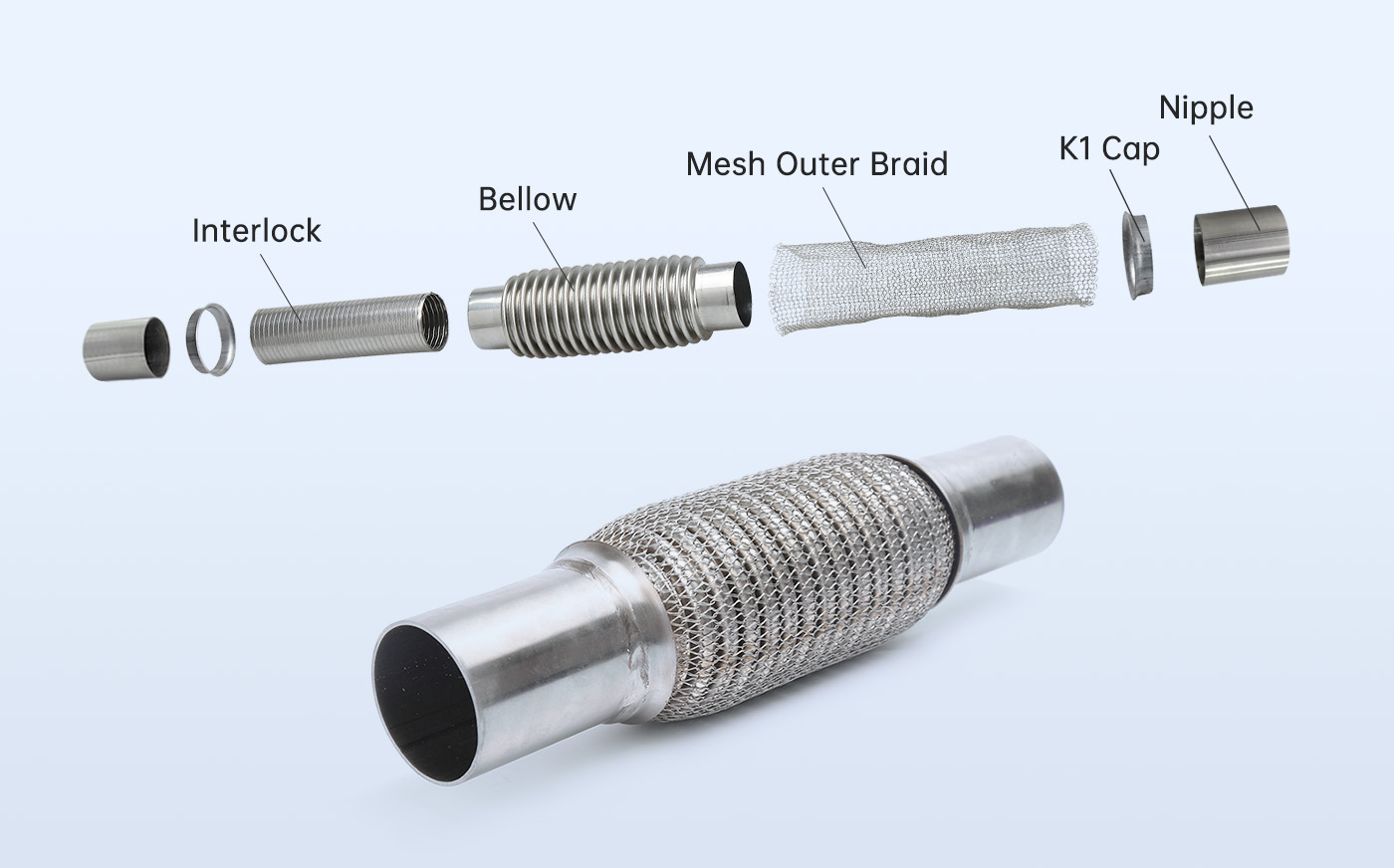

Braided or mesh, the outside you see is just one layer of the whole flexible pipe. Its function must look together with the bellows movement. The flex pipe you hold has bellows, outer braided mesh, and end fittings or sleeves. Need to know, the bellows is the core component that absorbs vibration and displacement. The outer mesh mainly limits the bellows’ range of motion, so it prevents tearing or deformation under extreme conditions.

Also, it protects from flying debris, thermal shocks, and wear caused by vibration. The bellows flexibility comes from each wave's extension, but the outer mesh acts as a “movement limit.” If the outer mesh is too tight, the compensation range of the bellows is significantly reduced, then insufficient flexibility. If too loose, the bellows may be overstretched over long-term vibration, that makes fatigue damage. So, when you see braided and mesh structures, you are looking at two different restriction methods. They are not a matter of right or wrong, just design choices for different working conditions. In production, we set mesh density, wire diameter, braid pitch, and even color all according to the vehicle type, engine displacement, installation location, or customer requirements.

Core differences between the two outer braid structures: restriction, flexibility, and frictionWhen

you truly understand how a flex pipe works, then you see why braided and mesh are different in engineering. Braided has higher braid density, tighter wires, and larger coverage. It is just like putting a stable protective layer over the bellows, keeping movement orderly and providing balanced support during continuous vehicle vibration. Because of high coverage, the contact area between the outer mesh and bellows is large, so friction is more evenly distributed. Therefore, braided structures are widely used in mainstream vehicles and suitable for regular roads, normal loads, and relatively stable exhaust routes.

Mesh or thin braid follows a completely different logic. You will notice its mesh is sparser, but sparse does not mean cutting corners—it means bellows can have greater freedom of movement. In our production process, the mesh structure’s braid pitch is set larger than conventional braided, so reduced coverage significantly increases bellows flexibility. This is good in large displacement, frequent vibration, or complex installation environments, it makes performance smoother. Also, because contact area is smaller, friction between the outer mesh and bellows actually decreases, which is different from many people’s intuition. Reduced friction means less long-term fatigue wear, this helps improve outer mesh durability. The only thing to note is lower restriction means bellows’ freedom increases, that will slightly raise vibration noise. And, under extreme conditions, the service life may be shorter than dense braiding. This is a structural logic, not a quality issue.

Materials, process, and manufacturing

Whether you choose braided or mesh, the ultimate stability mostly depends on the materials, machining accuracy, and process consistency of both the bellows and outer mesh. In our production, bellows usually use 304 or 201 stainless steel. 304 is better, it has higher corrosion resistance and toughness, so it is popular in overseas markets, but 201 is for cost-sensitive vehicles in milder environments. End fittings usually use aluminized steel or 409. 409 is good because it performs stably under high exhaust temperatures, so it is suitable for mass production.

For mesh structures, the bellows are generally fixed at 304. This is not just for durability, but also to maintain higher fatigue performance, because mesh relies more on bellows flexibility. Producing our own outer mesh allows control of density and tension, keeping the surface compact and smooth with no wire disorder, skipped stitches, or uneven tension. For many export projects, customers request specific colors or densities for the mesh, this can be easily achieved by adjusting machine tension and braiding angle in a self-made mesh factory. Many outsourced meshes, however, cannot maintain batch-to-batch consistency.

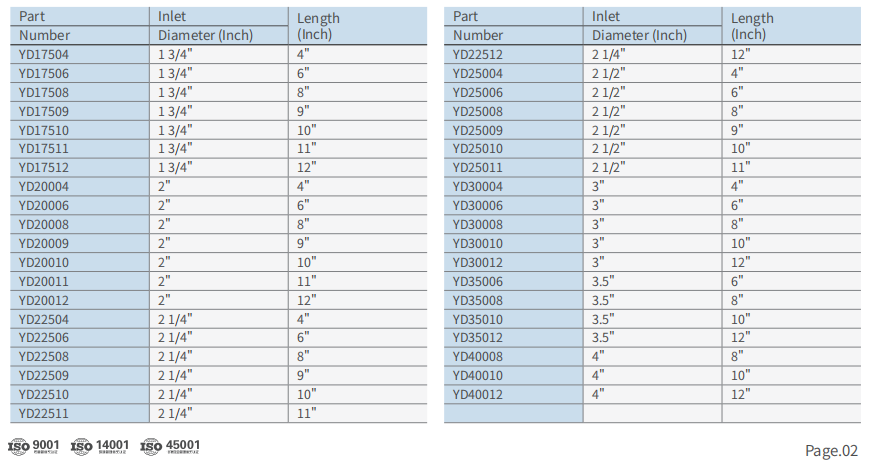

Dimension tolerances are very important, especially for mass production clients. Our standard mesh and braided sizes range from 1 3/4 inches to 4 inches in diameter, 4 inches to 12 inches in length, with inner diameter tolerance ±0.5mm and length tolerance ±3mm. For a multi-step product like a flex pipe, these figures reflect the precision of forming molds, welding positioning error control, uniformity of mesh tension, and stability of sleeve crimping, not just a result of a single process.

Why braided structures are more common

You might wonder why most outer meshes are still braided. The reason is simple: its balance is good. In terms of restriction, protection, and lifespan, it meets most requirements in daily use. On city roads or highways, engine vibration does not reach the flexibility range required by mesh, so dense braiding seems safer.

From a factory perspective, braided production is efficient, mature, and the appearance is more uniform, making it a habitual “industry standard” for many clients. Additionally, braided friction with bellows is more uniform, and noise control is easier, so it is suitable for noise-sensitive applications.

Therefore, for regular vehicles, stable conditions, and desire for good lifespan and balanced performance, braided is more suitable. If the flex pipe is installed near the rear axle, under the turbo, or in high-vibration engine locations, or if road conditions are rough, temperature differences large, and engine frequently switches high loads, mesh’s flexibility provides higher reliability.

For procurement, you do not need to overcomplicate the choice; just provide the working conditions, and we will offer a suitable solution based on structure, material, and braiding method, not the most expensive one.

Questions you may want to ask

Q1: Why do braided or mesh pipes vary slightly in mesh color or gloss between batches?

This is normal and need not worry you. Color, brightness, and surface reflection are affected by wire drawing batches, annealing temperature, and storage humidity. For example, higher temperature during wire drawing may slightly alter surface oxidation and gloss. Mesh left in the workshop for a long time may show minor color differences. These do not affect structural performance. What matters are wire strength, braid density, burr control, and tension consistency, which determine lifespan and wear resistance.

Q2: Why does mesh/thin braided feel softer than braided when squeezed? Does softness mean easier damage?

Softness comes from two factors: lower coverage and slightly wider bellows pitch, allowing greater axial and lateral deformation. The softness is meant to adapt to high-vibration environments, not cost-cutting. Softness does not equal shorter life, but requires careful installation to avoid additional stress from misaligned brackets or supports. For high-vibration pickup trucks, light trucks, or off-road vehicles, softness is an advantage, but installation must be precise.

Q3: For extremely low-noise configurations, should I choose braided or mesh?

For quiet exhaust systems, braided is safer. Its larger coverage and tighter weave reduce friction noise between bellows and mesh. Mesh’s open structure may produce slight rustling under high-frequency vibrations, noticeable mostly in modified exhaust systems, thin-wall pipes, or long-span layouts.

Q4: Why do “service life” claims vary greatly among manufacturers?

Exhaust pipe life is highly affected by working conditions, and testing methods vary. Some factories do simple swing tests, some perform thermal cycles, and some simulate full-vehicle vibration. Our factory tests bellows, mesh, and welds separately, then final product tests, giving conservative but realistic lifespan ranges. Claims of “over 5 years” are usually idealized tests, not real vehicle conditions.

Q5: Can a pipe’s quality be judged solely by appearance?

Only partially. Appearance indicates mesh flatness, weld uniformity, and bellows pitch, but cannot show wire composition, heat treatment, forming tolerances, or weld penetration, which determine lifespan. In our inspection process, appearance accounts for about one-third of checks; the rest comes from dimensional, material, and welding inspection. Judging solely by appearance may mislead you into thinking a visually good product is structurally superior.

Q6: For exhaust modification, can I directly use braided or mesh of the same size from existing models?

Modification environments are more complex. Original support points, tail weight, and bends are altered, changing pipe stress directions. Confirm three measurements: upstream tilt angle, engine vibration direction, and installation span. We often ask ODM clients to provide top-down installation photos or send old pipes for disassembly to observe bellows deformation, mesh friction direction, and weld stress signs, to determine braided or mesh.

Q7: Why do mesh/thin braided prices vary widely?

Wire specifications, braiding speed, bellows material, and sleeve type (aluminized steel or 409) affect price. Braiding speed is often overlooked; faster speeds to increase output can lead to uneven tension and local loosening over time. Cheap mesh is not necessarily bad, but you must know what part of the process is compressed and whether the pipe can handle the intended vehicle.

Q8: Does bellows pitch affect braided and mesh performance?

Yes, greatly. Denser pitch = stiffer; wider pitch = easier displacement. Softness is mostly from the bellows itself, not outer mesh. We adjust bellows pitch according to mesh type: mesh gets larger pitch for full flexibility, braided stays denser for support. Overly soft pipes usually result from overly wide pitch, not the mesh alone.

Q9: Some pipes show minor surface wear after six months—is this a quality issue?

If wear appears on raised points of the mesh outer layer, this is normal due to minor vehicle movement and contact with nearby heat shields or components. No penetration or local break = not a quality issue. Concentrated dents may indicate misaligned installation or overload.

Q10: If I want a custom mesh or braided flex pipe, what basic information should I provide?

Provide at least: working temperature range, space constraints, and lateral displacement. If unsure, sending the old pipe or detailed photos helps us analyze bellows fatigue, mesh friction direction, and weld stress to design a solution closer to actual conditions, rather than applying a standard part.

Summary

After understanding braided and mesh/thin braided flex pipes, then you will see they are not “better or worse,” they are just two designs for different conditions. Braided is balanced, durable, and stable under normal use. Mesh is more flexible, has lower friction, and absorbs vibration more smoothly, so it is suitable for special conditions and complex installations. Choosing must not rely on appearance, but consider working conditions, bellows material, braid density, and installation location. If you provide actual conditions, we can use production-line engineering experience to offer a professional solution, that includes bellows layers, pitch, and thickness selection.