Basic Structure and Common Materials of V Band Clamp

Outer Diameter Size

Groove Structure

Bolt Specification, Band Thickness and Tightening Effect

Surface Treatment and Packing of V Band Clamp

Customized V Band Clamp

Ending

In many round pipe connection situations, the V band clamp is always regarded as the most stable and simplest connection method. Whether it is the turbocharger system, automotive exhaust system, ventilation and smoke exhaust system, or various industrial equipment that require flange face connection, it is a commonly used and important accessory. Although the structure of the V band clamp does not look complicated, it has very strict requirements on size matching. Only when the groove width and groove depth of the clamp match the flange structure completely, it can ensure air tightness and mechanical stability after tightening.

If the clamp you choose does not match the flange very well, problems may appear during installation, such as cannot buckle on, cannot tighten, gap too large, and even during use may cause leakage, looseness, noise, or even burning at the connection under high temperature. To avoid these conditions, most factories will confirm the clamp size during the drawing design stage or trial production stage, and sometimes will buy one or two samples for test fitting. Confirming the size earlier is much more time-saving than rework or return in the later stage.

This article is written based on this kind of actual purchasing experience, and we hope it can help you judge faster and more accurately what kind of V band clamp is suitable for your project before you make the official order.

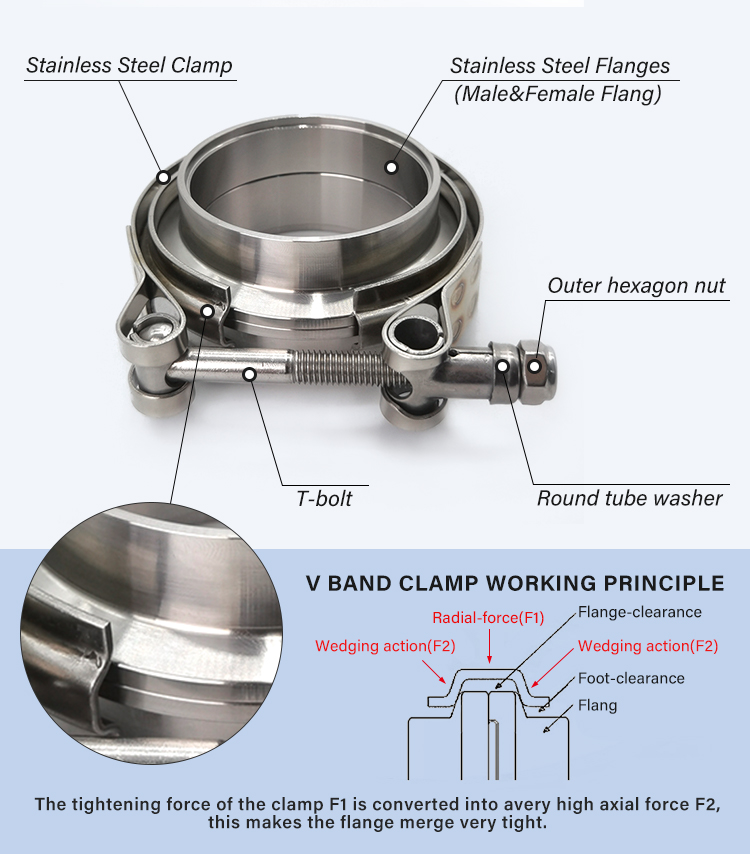

The V groove clamp usually consists of four parts, including stainless steel band, a ring with V groove, bolt and nut. The steel band plays the role of tightening, the ring fits with the flange slope surface, relying on the V groove to achieve even force, and the bolt and nut provide the final clamping force. When you tighten the bolt, the groove will press the pipe ends together tightly, and the force will distribute evenly, so it avoids point load, and this creates a vibration-resistant and pressure-resistant connection.

|  |

For materials, the most common ones are 201 and 304 stainless steel. 201 strength and appearance are not bad, and in normal temperature and light corrosion environments it can already meet most ventilation and smoke exhaust uses. But 304 has better temperature resistance and corrosion resistance, especially suitable for high temperature exhaust area, turbo area, diesel system, chemical pipeline and other positions with long-term high temperature and vibration. If your environment temperature is several hundred degrees Celsius and above, choosing 304 first is a safer decision. Although 304 cost is higher, from maintenance cost, stability, and lifetime, it is usually more economical.

Among all parameters of choosing V band clamp, the outer diameter is the most basic and direct one. If you use flanges, you need to confirm the flange outer diameter; if the clamp is installed directly on the pipe, then you must measure the pipe outer diameter. One thing to note is that the V band clamp will fit with the manifold, turbocharger or related flange surface after the thermal process during vehicle operation, this is to keep the sealing effect better, and after loosening and tightening, the clamp itself already has slight deformation, so if you want the best sealing effect, it is not recommended to reuse the V band clamp, even on pipes with the same outer diameter.

Among all matching items, the groove structure is the easiest part to make mistake, and also the part that causes the most rework. The reason why the V band clamp can achieve sealing is because the V groove of the ring can fit completely with the flange lip structure, and this fit depends on the precise matching of groove width and groove depth.

Different factories do not have unified flange machining standards. Even for the same 3 inch, 4 inch, 5 inch size, the groove design may be totally different. If the groove width is too narrow, the clamp cannot buckle on the flange; if the groove width is too wide, there will be gap when tightening and sealing will not be enough; if the groove depth is not correct, the force point will shift and after long-term vibration it may become loose. Because these details cannot be judged by eyes, when you are not sure, you can ask us for clamp and flange drawings, and compare parameter to parameter, not relying on impression. Based on our production experience, if you are doing project development or changing supplier, even if you have been using a certain size for a long time, we still suggest testing one sample first.

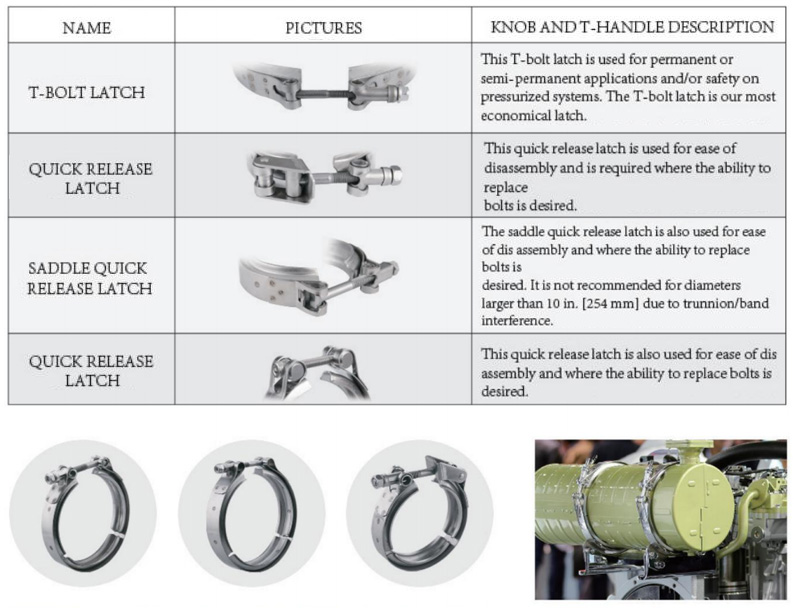

Besides basic size, bolt structure and band thickness also affect the clamp use effect. If your installation space is narrow, the bolt length or nut position will affect your installation experience directly. Under high-temperature environment, bolt material will also affect if it is easy to seize or deform. If you need to dismantle frequently, you can choose higher temperature resistant nut or self-locking nut.

The band thickness affects the overall strength of the clamp, but thicker is not always better. Band too thin causes insufficient clamping force, but too thick may cause installation difficulty or interfere with other parts in compact space. When choosing thickness, you should consider pipe diameter, vibration condition and flange structure. Our recommended band thickness is 1MM, but we can also make other thicknesses. If you need suggestions or bulk purchase for V groove clamps, please contact us.

Comparison of V-band clamps with different polishing levels

If you have certain requirement on the appearance of the clamp, we usually suggest you choose polishing. Polishing can reduce the small burrs and welding residue around the welding point, making the surface cleaner, and during batch assembly it is easier to clean. For some positions that are more visible, such as tail exhaust section or show car parts, the polished clamp will look more uniform and better for display.

If you need identification, you can choose laser LOGO. Laser marking has advantages like high temperature resistance, no color fading and not easy to wear, and it is helpful for brand identification or distinguishing different batches. Most customers put the LOGO in the middle of the band or near the bolt, so it can be seen after installation no matter how the clamp rotates. If you work with different project teams or multiple distributors, laser marking can also reduce the risk of mixing parts.

Before shipment, we will do size check, appearance check and structure tightening check for every batch. Normal type, polished type, quick release type and types with flange will have different packing methods. Usually small sizes will pack several pieces in one box, while big sizes have heavier weight, so the packing quantity is less. The volume of different sizes also changes, and you can refer to the following data of packing quantity and single box volume.

For example, 2.0" size (19*1.0 band width and thickness), the normal weight is 138 g, quick release version is around 161 g, and the flange weight is around 246 g. For 2.5" size, band width and thickness are still 191.0, normal weight is about 158 g, quick release is 181 g, flange weight is 302 g. The TV clamp between these two sizes can pack about 90 pieces in one box, and the single clamp volume is 37*37*25 cm, about 0.0342 m³.

The 3.0" size uses 22*1.0 band width and thickness, normal weight 237 g, quick release 263 g, flange 347 g. 3" is one of the most common sizes in exhaust systems, single clamp volume is 47*33*28 cm, about 0.0434 m³, and the usual packing is 60 pieces per box.

Bigger size like 5.0" uses 22*1.0 band width and thickness, single weight is around 327 g (normal) and 347 g (quick release), flange weight is 560 g. Big diameter V band clamps are usually for truck exhaust or industrial pipes, and because the volume is large, the packing quantity is around 50 pieces/box to avoid too heavy single box. The clamp volume is 44*33*36 cm, about 0.0522 m³.

Of course, no matter you choose with flange or without flange, polished or normal surface, standard structure or quick release structure, we can adjust packing method according to your project needs. In international delivery, reasonable packing quantity can avoid clamp deformation and also reduce shipping cost. If you have your own packing size or pallet specification, you can tell us and we will follow your size to check and prepare packing.

|  |

If your equipment structure is special or your using environment has extra requirements, you can consider customization. You can adjust band width and thickness, V angle and depth, bolt material and whether to make quick release structure. If you need regular maintenance during use, you can adjust the bolt position to make it easier to dismantle. In some limited-space situations, we can also make special-shape clamps, and this kind of requirement is not rare in equipment manufacturing industry.

When you start your next purchase or choose a suitable V band clamp for your project, you can check again the size, tolerance, flange structure and groove compatibility. If you still cannot confirm which size to choose, we can help you check the best combination according to your working condition and drawings.

If you want to confirm the quality first, we can provide samples for bulk orders, and you can test the fitting and tightening effect during the trial installation stage. For packing method, loading volume, MOQ or other requirements, you can also tell us anytime, and we will give you more specific plan according to your schedule.

If you need reliable V band clamps for your project, welcome to contact us.