Stainless Steel Custom Reinforced Bellows

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Metal bellows are flexible connectors that help absorb vibration, thermal expansion, or misalignment in piping and mechanical systems. They are often used where rigid connections would otherwise create stress or leakage. At YDCT, we offer different types of bellows that can be tailored for a range of pressures, temperatures, and movements. While some applications need only a simple single-layer bellow, others require more robust multi-layer or reinforced designs to meet heavier demands. | |||||||||

Flange:Flange shape as customers'requirementFlange periphery preset groove,Flange edge preset groove,welded with bellows.(Preferably the same material as the bellows)

Bellows:Stamping a metal plate into a circular shape,the thickness and profie shape of the plate depend on the usage conditions.

Pitch:Effect pressure resistance,durability,spring rate,etc.

Annule width:Effect flexibility,yielding.pressure resistance,durability,and spring rate etc.

Distance=(OD-ID)/2

Effective diameter-=(OD+ID)/2

Effective area=π*D2/4

| Material Selection: Parameter Introduction | |||||

|---|---|---|---|---|---|

| Material | Temperature (°C) | Characteristic | Heat resistance | Durability | Corrosive |

| SUS304L | -196 ~ 400 | Austenite stainless steel | B | B | B |

| SUS316L | -250 ~ 450 | Corrosion resistance, heat resistance, excellent resistance to hydrogen chloride | B | B | B+ |

| Precipitation hardening stainless steel | |||||

| AM350 | -200 ~ 315 | High strength, weak magnetism, general application, poor resistance to corrosive gases | B | A+ | B |

| Nickel-based heat-resistant, corrosion-resistant steel | |||||

| Hastelloy C-276 / Hastelloy C-22 | -200 ~ 700 | Excellent corrosion resistance, strong anti-oxidation and anti-halide capabilities | A | A | A |

| Inconel 625 / Inconel 718 | -200 ~ 980 / -253 ~ 700 | Acid resistance, high temperature resistance | A | A | A |

| Haynes 242 | -251 ~ 698 | Strong anti-oxidation capability, excellent stability in high-temperature environments | A | A+ | A+ |

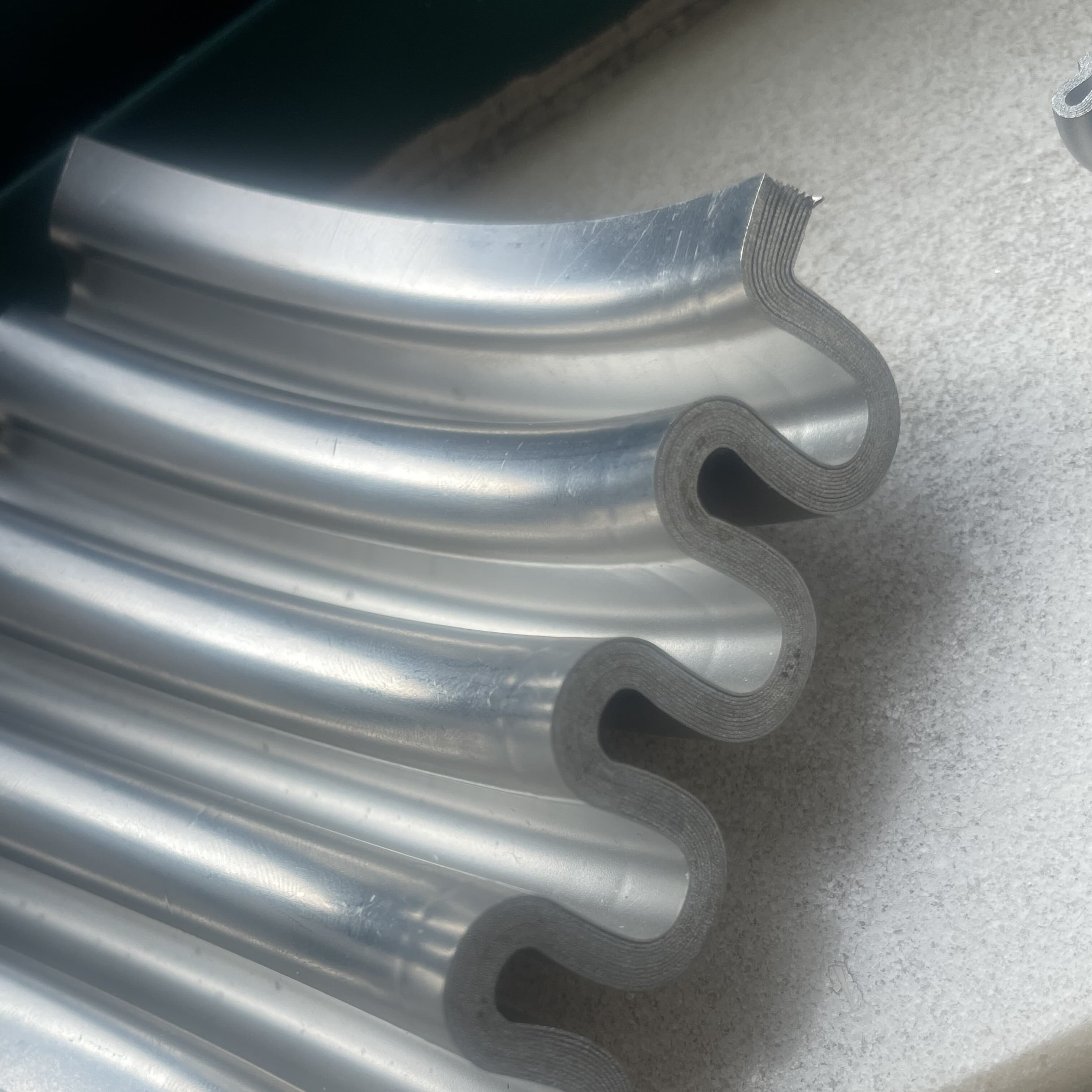

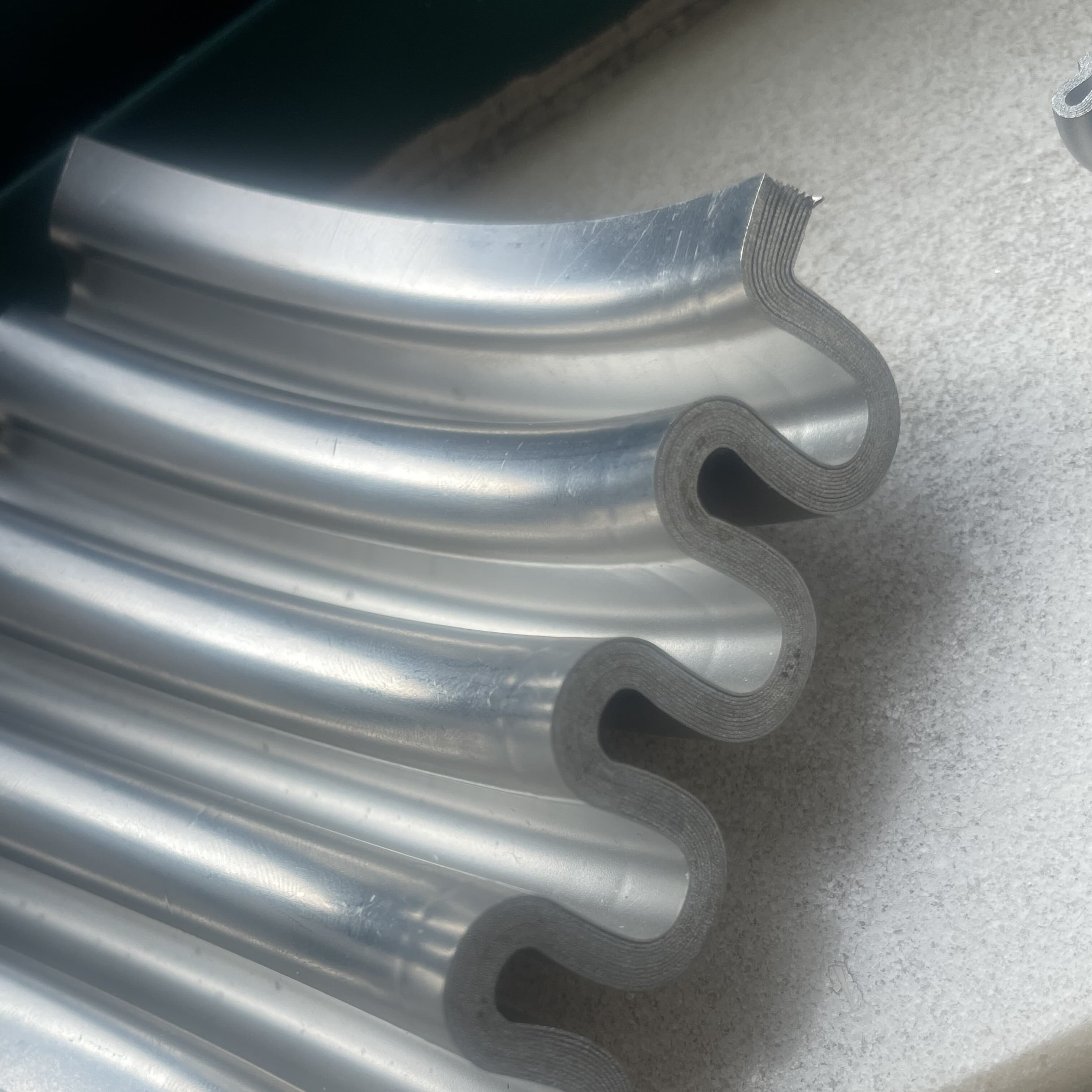

Rating Key: A+: Excellent, A: Good, B: Fair / Acceptable, C: Poor  Single-layer vs. Double-layer Bellows  Multi-layer Bellows Cross-section The wave height, wall thickness, and number of layers decide how a metal bellow works. A higher wave gives more flexibility and movement, but the pressure resistance becomes lower. A thicker wall can take more pressure but makes the bellow harder to move. We usually choose the structure based on your working condition. Single-layer bellows are light and flexible. Multi-layer types are stronger and last longer, but they are heavier and cost more. They are used in systems with high temperature, vibration, or pressure changes. YDCT can produce bellows by hydraulic forming, roll forming, or edge welding. Each method fits different sizes and applications. Hydraulic and roll forming are common for exhaust or industrial use, while edge-welded bellows are used for vacuum or precision equipment. Ends can be made with flanges, threaded fittings, or welded pipes. YDCT can also follow your drawings or samples. The temperature and pressure range depends on material and layer number. Our factory makes bellows for automotive exhaust, industrial machinery, HVAC, and other systems. The products are made under ISO 9001 quality control and designed for long working life without leakage or pollution. | |||||

Flange:Flange shape as customers'requirementFlange periphery preset groove,Flange edge preset groove,welded with bellows.(Preferably the same material as the bellows)

Bellows:Stamping a metal plate into a circular shape,the thickness and profie shape of the plate depend on the usage conditions.

Pitch:Effect pressure resistance,durability,spring rate,etc.

Annule width:Effect flexibility,yielding.pressure resistance,durability,and spring rate etc.

Distance=(OD-ID)/2

Effective diameter-=(OD+ID)/2

Effective area=π*D2/4

| Material Selection: Parameter Introduction | |||||

|---|---|---|---|---|---|

| Material | Temperature (°C) | Characteristic | Heat resistance | Durability | Corrosive |

| SUS304L | -196 ~ 400 | Austenite stainless steel | B | B | B |

| SUS316L | -250 ~ 450 | Corrosion resistance, heat resistance, excellent resistance to hydrogen chloride | B | B | B+ |

| Precipitation hardening stainless steel | |||||

| AM350 | -200 ~ 315 | High strength, weak magnetism, general application, poor resistance to corrosive gases | B | A+ | B |

| Nickel-based heat-resistant, corrosion-resistant steel | |||||

| Hastelloy C-276 / Hastelloy C-22 | -200 ~ 700 | Excellent corrosion resistance, strong anti-oxidation and anti-halide capabilities | A | A | A |

| Inconel 625 / Inconel 718 | -200 ~ 980 / -253 ~ 700 | Acid resistance, high temperature resistance | A | A | A |

| Haynes 242 | -251 ~ 698 | Strong anti-oxidation capability, excellent stability in high-temperature environments | A | A+ | A+ |

Rating Key: A+: Excellent, A: Good, B: Fair / Acceptable, C: Poor  Single-layer vs. Double-layer Bellows  Multi-layer Bellows Cross-section The wave height, wall thickness, and number of layers decide how a metal bellow works. A higher wave gives more flexibility and movement, but the pressure resistance becomes lower. A thicker wall can take more pressure but makes the bellow harder to move. We usually choose the structure based on your working condition. Single-layer bellows are light and flexible. Multi-layer types are stronger and last longer, but they are heavier and cost more. They are used in systems with high temperature, vibration, or pressure changes. YDCT can produce bellows by hydraulic forming, roll forming, or edge welding. Each method fits different sizes and applications. Hydraulic and roll forming are common for exhaust or industrial use, while edge-welded bellows are used for vacuum or precision equipment. Ends can be made with flanges, threaded fittings, or welded pipes. YDCT can also follow your drawings or samples. The temperature and pressure range depends on material and layer number. Our factory makes bellows for automotive exhaust, industrial machinery, HVAC, and other systems. The products are made under ISO 9001 quality control and designed for long working life without leakage or pollution. | |||||

Metal bellows are used wherever flexibility, movement absorption, or vibration damping is required, but the specific use can vary widely depending on your system. To give you a clearer picture, here are some common questions we hear from our customers:

Q: Can these bellows handle automotive exhaust systems?

A: Yes, they're often installed in exhaust lines to absorb engine vibration and thermal expansion. We provide bulk supplies of braided exhaust flex pipes that fit most vehicles. For applications requiring higher-strength or multi-layer bellows, especially for heavy-duty or high-performance vehicles, you can contact us to arrange custom designs tailored to your needs.

Q: Are they suitable for industrial pipelines?

A: Absolutely. You’ll see them in chemical plants, petrochemical pipelines, water treatment systems, and other industrial settings. They can compensate for misalignment or thermal changes, but keep in mind that very large diameters or extreme pressures may require custom design considerations.

The right choice depends on operating temperature, vibration levels, space constraints, and material preferences. Sometimes a simple single-layer bellow is enough, sometimes a multi-layer reinforced solution is better, and we'll guide you on both the pros and the trade-offs.

Metal bellows are used wherever flexibility, movement absorption, or vibration damping is required, but the specific use can vary widely depending on your system. To give you a clearer picture, here are some common questions we hear from our customers:

Q: Can these bellows handle automotive exhaust systems?

A: Yes, they're often installed in exhaust lines to absorb engine vibration and thermal expansion. We provide bulk supplies of braided exhaust flex pipes that fit most vehicles. For applications requiring higher-strength or multi-layer bellows, especially for heavy-duty or high-performance vehicles, you can contact us to arrange custom designs tailored to your needs.

Q: Are they suitable for industrial pipelines?

A: Absolutely. You’ll see them in chemical plants, petrochemical pipelines, water treatment systems, and other industrial settings. They can compensate for misalignment or thermal changes, but keep in mind that very large diameters or extreme pressures may require custom design considerations.

The right choice depends on operating temperature, vibration levels, space constraints, and material preferences. Sometimes a simple single-layer bellow is enough, sometimes a multi-layer reinforced solution is better, and we'll guide you on both the pros and the trade-offs.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS