Table of Contents

About Exhaust Bellows and Flex Pipe

What is an Exhaust Flex Pipe

What is an Exhaust Bellows

Which One Should You Choose?

Why Are Many Bellows More Expensive Than Flex Pipe?

Points You Should Pay Attention To

Durability of Exhaust Bellows and Flexible Exhaust Pipes

How to Determine if a Supplier is Reliable

Conclusion

About Exhaust Bellows and Flex Pipe

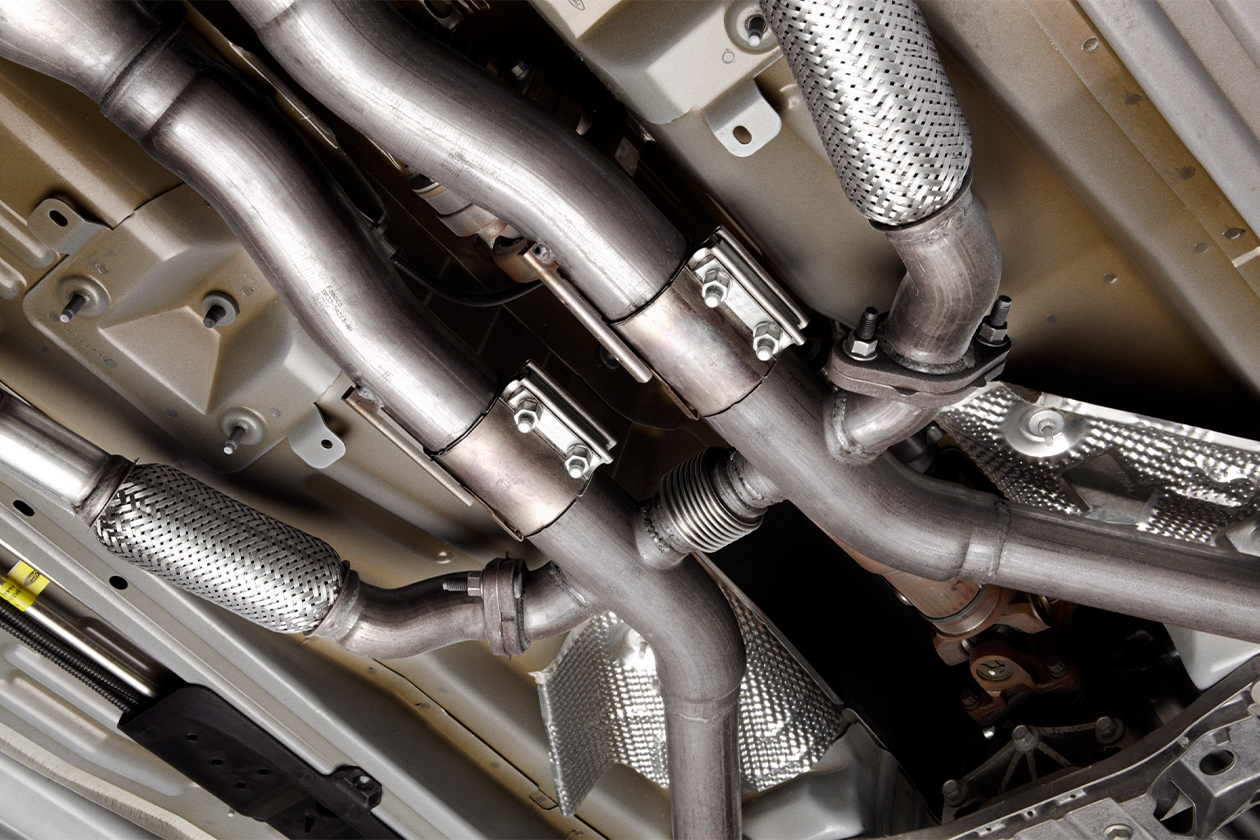

Online, you may often see exhaust bellows and flex pipe placed in the same category. This happens because they can both appear on the same exhaust system, looking like “flexible structures.” But from an engineering perspective, their working principles, structural strength, and application scenarios are completely different. If you are comparing these two products, it usually means your system involves both vibration issues and possibly thermal expansion or displacement compensation needs, so you need to judge accurately which one to use.

Many people simply think of exhaust bellows as “soft tubes without braided layers,” as if it is just removing the outer braid of a flex pipe and keeping the internal metal corrugation. But in fact, the corrugation strength and design logic of these two types of products are completely different. The corrugation inside a flex pipe is usually designed to cooperate with the braid for vibration absorption, with wall thickness, waveform, and stiffness leaning toward flexibility; while a real bellows used for compensation must withstand axial compression, thermal expansion, backpressure, and long-term cycling. Its corrugation geometry, manufacturing method, layer distribution, and compensation amount are of higher engineering grade.

Simply put: they may look similar, but their functions are completely different. The following content will help you truly distinguish their structure, application logic, and durability performance, which can reduce communication costs during bulk procurement of corrugated pipes or other stainless steel compensators and help avoid choosing the wrong product for inappropriate operating conditions.

What is an Exhaust Flex Pipe

In the exhaust system, the core function of a flex pipe is very straightforward: to provide a flexible section that can absorb vibration and buffer small displacements, preventing the exhaust line from being pulled due to engine shake, road impact, or thermal expansion and contraction. Its basic structure consists of a stainless steel corrugated tube, an outer braided layer (single braid, double braid, mesh braid, or thin braid), clamps, and sometimes an inner braided layer, expansion joints, or extended connectors. Among them, the corrugated tube provides flexible movement, the braid bears mechanical limits and vibration resistance, the interlock liner or inner braid offers inner wall support to reduce turbulence and noise, and the connector is for easier installation.

|  |

|  |

Flex pipes are more suitable for exhaust systems under standard conditions, such as passenger vehicles and some modified vehicles. In these environments, displacement is limited, temperature and pressure changes are relatively controllable, and the vibration absorption provided by the flexible pipe is enough to protect key parts like catalytic converters, turbo outlets, hangers, and welds. Our stainless steel hoses can also be customized in different lengths, diameters, shapes, material strength, and connection types to suit motorcycles, ships, heavy trucks, industrial equipment, and other applications.

Ultimately, the value of a flex pipe still focuses on “vibration suppression.” It reduces axial or lateral forces caused by resonance, keeping the exhaust system stable. If your exhaust environment is conventional and requires a cost-effective, flexible, and adaptable connection, a flex pipe usually meets the demand.

What is an Exhaust Bellows

If flex pipe can be regarded as a flexible connection focusing on “vibration absorption,” then bellows are true “compensation components.” Flex pipe relies on the corrugation cooperating with the braid to limit displacement; its structure is light, and the flexible range is limited. The design purpose of bellows is to continuously handle axial changes caused by thermal expansion in high-temperature, high-displacement, and high-cycle operating conditions.

Exhaust bellows structures can be single-layer, double-layer, triple-layer, or composed of dozens of thin metal layers in a multi-layer composite wall. The more layers, the higher the stability and fatigue life of each corrugation, and the greater the temperature difference and displacement it can withstand. Engineering attention here is not on “vibration suppression,” but on “compensation capability,” “fatigue life,” “cycling stability,” and “controllable failure modes.”

In most high-temperature exhaust systems, bellows are combined with flanges, limit rings, or outer protective sleeves to form complete compensation assemblies. They are used in commercial vehicle exhaust pipelines, construction machinery, boiler exhaust, generator sets, high-temperature flue gas systems, and other equipment with continuous thermal expansion.

Which One Should You Choose?

You don’t actually need to repeatedly compare “which is better,” because flex pipe and bellows are not interchangeable. If your system mainly deals with vibration absorption, small displacement, and installation error compensation, and the exhaust temperature is within the normal range of conventional engines, flex pipe is more suitable.

But when the system experiences clear thermal expansion, axial stretching, and continuous high temperature, bellows, as a corrugated compensator, is the wise choice. It provides “structural compensation,” not just “vibration reduction,” and often, the lack of compensation will directly affect system life.

If you are still unsure, you can tell us the following four operating parameters:

Temperature range

Displacement direction and amount

Support and fixing method

Backpressure and vibration environment

We can combine these to help you select the product suitable for your system.

Why Are Many Bellows More Expensive Than Flex Pipe

The reason bellows are more expensive than flex pipe is simple—they do a more “demanding” job. Bellows have more corrugation layers, use more metal, and have more complex manufacturing processes. They need precise forming to ensure each expansion and contraction is completed smoothly without issues. They also undergo various tests to ensure they can withstand high temperatures and repeated axial stretching for a long time without cracking or failing.

Flex pipe has a simple structure and is mainly used to absorb engine vibration and compensate for small displacements. It uses less material, is easier to manufacture, and naturally costs less. Especially in high-temperature, long-running, or high-durability-demand environments, only bellows can work stably, so the price is correspondingly higher.

Points You Should Pay Attention To

Q: Can flex pipe and bellows be used together?

A: Yes. In some complex exhaust systems, both flex pipe and bellows can be used. Flex pipe absorbs engine vibration and small displacement, while bellows absorb thermal expansion and large displacement. A proper combination makes the exhaust system both stable and durable.

Q: What about material selection?

A: Flex pipe commonly uses 304 or 321 stainless steel, sufficient for ordinary automotive exhaust systems. Bellows materials need to remain stable under high temperature, high pressure, and corrosive gases. Especially for some marine bellows, high-strength 316L stainless steel, high alloys, nickel-based alloys, or multi-layer composite structures are used to extend service life.

Q: Does flex pipe affect exhaust sound?

A: To some extent, yes. Because flex pipe can buffer vibration and minor resonance, it can reduce vibration transmission, which may slightly affect exhaust sound. Bellows focus more on displacement compensation and have little effect on sound.

Q: What should be considered for logistics and packaging?

A: Flex pipe is usually protected with foam, paper tubes, or plastic bags, then packed in cartons or pallets. Bellows, due to multiple corrugation layers and precise structure, require stricter packaging, often with protective plates or filling materials on the corrugated section to prevent deformation during transport. Proper logistics packaging ensures the product reaches the customer in its original state.

Q: Any installation differences?

A: Flex pipe has relatively loose installation precision and can tolerate slight bending or misalignment. Bellows require high axial alignment; misalignment may cause stress concentration, affecting compensation performance and life.

Q: Which is more suitable for modification or lightweight systems?

A: For modified vehicles or lightweight exhaust systems, flex pipe is preferred due to its large flexibility, light weight, low cost, and ease of installation and customization. Bellows, although durable and fatigue-resistant, are heavier and more expensive, generally used in high-power or long-running systems.

Durability of Exhaust Bellows and Flexible Exhaust Pipes

You may think flex pipe is not durable, but often damage is not caused by the pipe itself. The most typical issue is improper support layout, causing the exhaust weight to directly press on the flexible section. Under such stress, any braid will fatigue quickly. Moreover, continuous torsion, misalignment during installation, or chassis water accumulation causing outer corrosion can cause early braid failure. In addition, turbocharged systems under high backpressure produce pulsating shocks, and the inner corrugation may over-expand in short cycles, further shortening service life. Most importantly, flex pipe is not a high-temperature compensator; it mainly handles vibration and small displacement. If used where bellows are required, it will inevitably fatigue early—this is determined by structural principles.

Compared to flex pipe, bellows have a clearly longer life because they are designed to withstand real thermal expansion and displacement. The most important parameters of a corrugated tube are the peaks and valleys, determining compensation, stiffness, and fatigue life. Multi-layer structures are not just thicker; they distribute metal stress through inner and outer layers, keeping deformation per layer low, improving temperature resistance and service life. In high-temperature or high-displacement systems, bellows often include inner sleeves, balance rings, and guide rings to control medium erosion, stabilize corrugation, and prevent local buckling during compression. This is the typical corrugated compensator structure, which does not exist in flex pipe. Therefore, flex pipe cannot maintain stable life under continuous high temperature, significant axial expansion, or long-term operation of large-displacement engines.

How to Determine if a Supplier is Reliable

When selecting a supplier of exhaust flexible components, do not be confused by marketing or price gimmicks. The real indicators of factory strength are reliable raw material sources, stable welding quality, standard corrugation forming, fatigue test reports, strict dimensional tolerance, and detailed samples.

If you need to procure suitable stainless steel exhaust hoses and bellows, you can contact us at any time. YDCT, as a leading Chinese corrugated pipe manufacturer, has more than thirty years of experience in automotive stainless steel hoses, exhaust bellows, and related products, serving clients in over 100 countries and regions. We are equipped with advanced seamless tube forming, braid forming workshops, precision welding workshops, CNC stamping workshops, and bellows testing laboratories, with monthly production capacity up to 350,000 units.

We also provide custom services according to client needs, including different materials, corrugation layers, lengths, and connection types for exhaust flexible components, supporting welding, clamps, flanges, and other installation methods. Every batch is strictly inspected and sample-verified before shipment to ensure performance meets actual operating conditions. No matter your application, YDCT can provide reliable solutions to keep your exhaust system stable and reduce maintenance costs.

Conclusion

Whether you are choosing flexible components for vehicles, construction machinery, generator sets, or industrial exhaust systems, the key is not to judge which is “better” between bellows and flex pipe, but to understand which one truly suits your operating conditions. Flex pipe is mainly used to absorb vibration and compensate for small displacement, while bellows are designed for high-temperature environments and axial expansion to handle thermal expansion and large displacement. They solve different types of operating needs, so costs and service life differ. As long as you know your system’s temperature range, displacement direction, backpressure, and installation conditions, you can make a reasonable choice. If you are still unsure, you can contact us, and we will help you match the right structure, saving your valuable time.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS