Stainless Steel Exhaust Band Seal Clamp

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

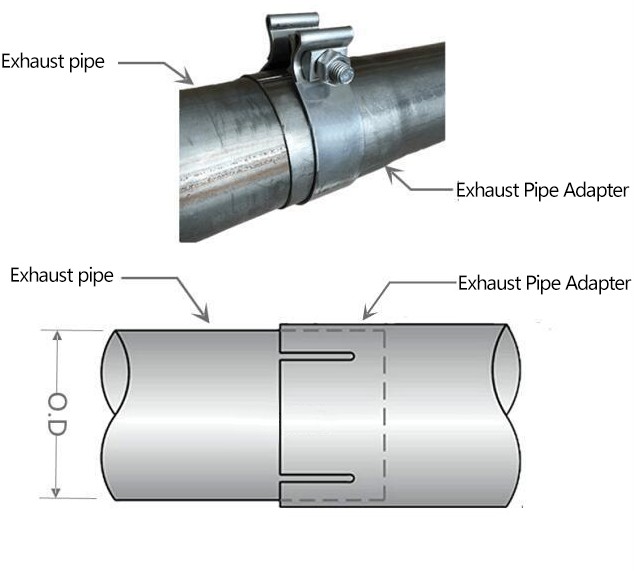

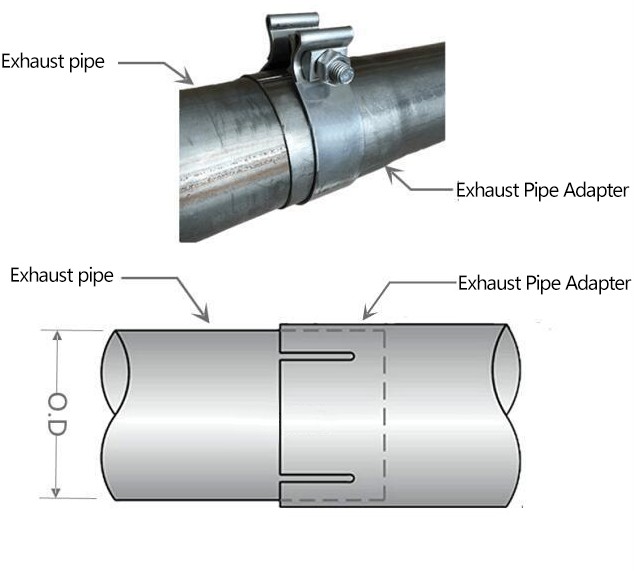

| Stainless steel band clamps are mainly used for connecting and sealing between exhaust pipes, flex pipes, mufflers and catalytic sections. The function is to let two pipes hold together firmly without welding and without pressing the pipe out of shape, which makes it suitable for jobs that need repeated removal or easy service. Passenger cars, pickup trucks, commercial vehicles and some equipment use this type widely, and repair shops and exhaust fabrication also use it often, especially when the space is tight or welding is not preferred. | |||||||||

YDCT O type exhaust band clamp is made by stainless steel band, bolt, nut and reaction block. The band material can be SS304, SS409 or carbon steel, and the bolt, nut and spacer are carbon steel. The normal size range is from 1 3/4” to 7”, with standard band width 1.25 inch (about 32mm) and thickness 1.8mm. The band arc is formed by fixed tooling to keep even pressure on the overlap joint and give stable sealing performance.

The I-shape reaction block (inner spacer) helps spread the force during tightening and avoids the bolt pressing directly on the band, so the clamp can keep its shape under higher torque. Bolt grade can be 8.8 or 10.9, and the nuts are made according to DTF anti-loose standard. Normally it is not necessary to add lockpatch, but we can add it if the project requires.

During production we check the band rebound, the fit between spacer and band, bolt torque retention and the gap after tightening, so the clamp stays consistent in bulk orders. The standard installation torque is 30 N·m. Regular packing is bag packing with 50 or 100 pcs per bag and then carton packing. For big orders we can offer customized packing or pallet service.

We also supply the inner-liner type band clamp. This structure has an extra inner layer to increase the contact area after installation, giving better sealing on old pipes or light deformation joints.

| Size(inch) | Exhaust Pipe |

| Outside Diameter | |

| 1 3/4 | 45mm |

2 | 51mm |

| 2 1/4 | 57mm |

| 2 1/2 | 63mm |

| 2 3/4 | 70mm |

| 3 | 76mm |

| 3 1/2 | 89mm |

| 4 | 102mm |

| 4 1/2 | 114mm |

| 5 | 127mm |

| 6 | 152mm |

| 7 | 178mm |

FAQ

1. Will the inner spacer spin? Can you press it tight?

Normally it will not spin. We check the fit between spacer and band during forming. If your project needs a tighter fit, we can adjust the pressing depth.

2. Can you add lockpatch on the screw threads?

Yes, we can. But our nuts are made under DTF anti-loose standard, so normally the lockpatch is not necessary.

3. My pipe OD is 2.5" (63.5mm). Why is the clamp size suggested 60mm?

For overlap joint the clamp needs some compression range, so the clamp ID is usually slightly smaller than the pipe OD. For 2.5” pipe, about 60mm clamp is normal.

4. Can you make Torca-style or lap joint band clamp?

Yes. We can make O type, inner liner type, reaction-block type and lap joint type, or produce according to sample and drawing.

5. Do you support marking, chamfering or small custom works?

Yes, we can do marking, chamfering and adjust band width or bolt kit based on requirement.

YDCT O type exhaust band clamp is made by stainless steel band, bolt, nut and reaction block. The band material can be SS304, SS409 or carbon steel, and the bolt, nut and spacer are carbon steel. The normal size range is from 1 3/4” to 7”, with standard band width 1.25 inch (about 32mm) and thickness 1.8mm. The band arc is formed by fixed tooling to keep even pressure on the overlap joint and give stable sealing performance.

The I-shape reaction block (inner spacer) helps spread the force during tightening and avoids the bolt pressing directly on the band, so the clamp can keep its shape under higher torque. Bolt grade can be 8.8 or 10.9, and the nuts are made according to DTF anti-loose standard. Normally it is not necessary to add lockpatch, but we can add it if the project requires.

During production we check the band rebound, the fit between spacer and band, bolt torque retention and the gap after tightening, so the clamp stays consistent in bulk orders. The standard installation torque is 30 N·m. Regular packing is bag packing with 50 or 100 pcs per bag and then carton packing. For big orders we can offer customized packing or pallet service.

We also supply the inner-liner type band clamp. This structure has an extra inner layer to increase the contact area after installation, giving better sealing on old pipes or light deformation joints.

| Size(inch) | Exhaust Pipe |

| Outside Diameter | |

| 1 3/4 | 45mm |

2 | 51mm |

| 2 1/4 | 57mm |

| 2 1/2 | 63mm |

| 2 3/4 | 70mm |

| 3 | 76mm |

| 3 1/2 | 89mm |

| 4 | 102mm |

| 4 1/2 | 114mm |

| 5 | 127mm |

| 6 | 152mm |

| 7 | 178mm |

FAQ

1. Will the inner spacer spin? Can you press it tight?

Normally it will not spin. We check the fit between spacer and band during forming. If your project needs a tighter fit, we can adjust the pressing depth.

2. Can you add lockpatch on the screw threads?

Yes, we can. But our nuts are made under DTF anti-loose standard, so normally the lockpatch is not necessary.

3. My pipe OD is 2.5" (63.5mm). Why is the clamp size suggested 60mm?

For overlap joint the clamp needs some compression range, so the clamp ID is usually slightly smaller than the pipe OD. For 2.5” pipe, about 60mm clamp is normal.

4. Can you make Torca-style or lap joint band clamp?

Yes. We can make O type, inner liner type, reaction-block type and lap joint type, or produce according to sample and drawing.

5. Do you support marking, chamfering or small custom works?

Yes, we can do marking, chamfering and adjust band width or bolt kit based on requirement.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS