Wire Spring Clamps for Low Pressure Hose Connections

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wire spring clamps are a practical fastening solution for low pressure hose connections. You typically use them on oil hoses, air hoses, water hoses, and internal pipelines of household appliances.This product relies on spring wire elasticity instead of screw tightening. Installation is fast and stable, helping reduce assembly time in production lines. You can choose single wire or double wire structures, as well as carbon steel with zinc plating or stainless steel 304.Standard sizes are available, and the minimum order quantity starts from 100 pcs. | |||||||||

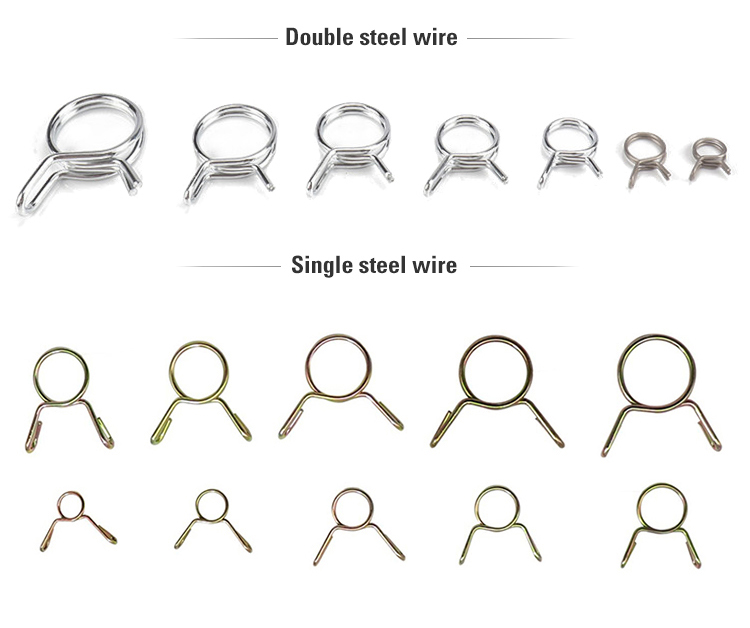

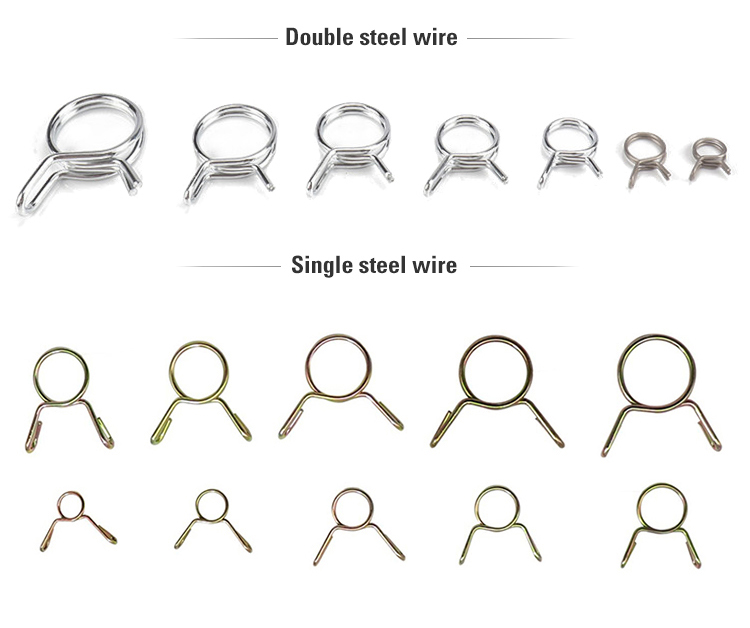

Wire Spring Clamps Construction

Wire spring clamps are available in single wire and double wire types.Single wire spring hose clamps use the most basic structure with minimum material usage. The cost is lower, and the clamp mainly holds the hose in position rather than compensating system movement.Double wire spring clamps use two parallel spring wires. This structure distributes the pressure more evenly around the hose circumference and improves sealing stability when hose outer diameter tolerance varies.

We also produce another type: Spring Band Clamps. If your pipe is used in high temperature and high pressure environments, like car engines, please choose the band type. Its 360° precision design and uniform sealing performance are much better for these jobs.But if you only use it for common washing machine drainage or simple air hose connections, the Wire Spring Clamp is your best choice. It has the best price and is the fastest to install.

| Feature | Wire Spring Clamp | Spring Band Clamp |

| Sealing Mode | Line Contact: High local pressure, "bites" into the hose. | 360° Surface Contact: Uniform pressure distribution, superior sealing. |

| Material | Carbon Spring Steel or SS304. | 65Mn / 60Si2Mn: High-strength manganese steel for constant tension. |

| Tension Style | Fixed mechanical clamping. | Constant Tension: Automatically compensates for hose expansion/contraction. |

| Surface Finish | Zinc plating (Color/White/Blue-White). | Full range: Color Zinc, Dacromet (1000h salt spray), Nickel, Electrophoresis. |

| Hose Protection | High local pressure might mark soft hoses. | Smooth, burr-free edges prevent hose damage. |

Wire Spring Clamps Material and Surface Treatment Options

Wire spring clamps can be produced from carbon steel or stainless steel 304.

Carbon steel clamps are commonly supplied with zinc plating, including colored zinc, white zinc, or blue-white zinc. These finishes provide basic corrosion resistance and good cost control for large-volume supply.

Stainless steel 304 wire spring clamps offer natural rust resistance and are suitable for humid or outdoor environments.

Wire Spring Clamps Construction

Wire spring clamps are available in single wire and double wire types.Single wire spring hose clamps use the most basic structure with minimum material usage. The cost is lower, and the clamp mainly holds the hose in position rather than compensating system movement.Double wire spring clamps use two parallel spring wires. This structure distributes the pressure more evenly around the hose circumference and improves sealing stability when hose outer diameter tolerance varies.

We also produce another type: Spring Band Clamps. If your pipe is used in high temperature and high pressure environments, like car engines, please choose the band type. Its 360° precision design and uniform sealing performance are much better for these jobs.But if you only use it for common washing machine drainage or simple air hose connections, the Wire Spring Clamp is your best choice. It has the best price and is the fastest to install.

| Feature | Wire Spring Clamp | Spring Band Clamp |

| Sealing Mode | Line Contact: High local pressure, "bites" into the hose. | 360° Surface Contact: Uniform pressure distribution, superior sealing. |

| Material | Carbon Spring Steel or SS304. | 65Mn / 60Si2Mn: High-strength manganese steel for constant tension. |

| Tension Style | Fixed mechanical clamping. | Constant Tension: Automatically compensates for hose expansion/contraction. |

| Surface Finish | Zinc plating (Color/White/Blue-White). | Full range: Color Zinc, Dacromet (1000h salt spray), Nickel, Electrophoresis. |

| Hose Protection | High local pressure might mark soft hoses. | Smooth, burr-free edges prevent hose damage. |

Wire Spring Clamps Material and Surface Treatment Options

Wire spring clamps can be produced from carbon steel or stainless steel 304.

Carbon steel clamps are commonly supplied with zinc plating, including colored zinc, white zinc, or blue-white zinc. These finishes provide basic corrosion resistance and good cost control for large-volume supply.

Stainless steel 304 wire spring clamps offer natural rust resistance and are suitable for humid or outdoor environments.

Wire Spring Clamps Dimensional Consistency

Wire spring clamps have a simple forming process and stable geometry. Dimensional consistency between batches is easy to control, which is important for automated or semi-automated hose assembly lines.

With basic tools such as flat pliers or clamp pliers, installation can usually be completed within about two seconds, helping reduce labor time in mass production.

Wire Spring Clamps Customization

In addition to standard specifications, custom wire spring clamps are supported.

We can develop non-standard sizes or special clamp structures based on your requirements, including changes in wire diameter, inner diameter, and forming shape.

For non-standard tooling, the typical minimum order quantity is 50,000 pcs, which is required to share tooling cost.

Packaging Options for Bulk Supply

Custom packaging is available, including cross-border box sets. You can define quantity per box, surface finish combination, and labeling format. Mixed-size assortments are commonly used for online and distributor channels.

Free packaging design support is available to match your sales model.

YDCT Quality System and Compliance

All wire spring clamps are produced under IATF 16949 automotive quality management system.

Products comply with RoHS environmental requirements and MA certification standards, ensuring stable quality control and traceability for bulk orders.

Wire Spring Clamps Dimensional Consistency

Wire spring clamps have a simple forming process and stable geometry. Dimensional consistency between batches is easy to control, which is important for automated or semi-automated hose assembly lines.

With basic tools such as flat pliers or clamp pliers, installation can usually be completed within about two seconds, helping reduce labor time in mass production.

Wire Spring Clamps Customization

In addition to standard specifications, custom wire spring clamps are supported.

We can develop non-standard sizes or special clamp structures based on your requirements, including changes in wire diameter, inner diameter, and forming shape.

For non-standard tooling, the typical minimum order quantity is 50,000 pcs, which is required to share tooling cost.

Packaging Options for Bulk Supply

Custom packaging is available, including cross-border box sets. You can define quantity per box, surface finish combination, and labeling format. Mixed-size assortments are commonly used for online and distributor channels.

Free packaging design support is available to match your sales model.

YDCT Quality System and Compliance

All wire spring clamps are produced under IATF 16949 automotive quality management system.

Products comply with RoHS environmental requirements and MA certification standards, ensuring stable quality control and traceability for bulk orders.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS