In an exhaust system, the exhaust flex coupler is often not the part you look at first.You may pay more attention to pipe diameter, muffler design, or whether the material is stainless steel. But in real use, many early exhaust failures actually start from this small flexible section.

If you are comparing different exhaust flex coupler products, or hesitating between several similar-looking product pages with close prices, this article is not written to tell you which one is “the best”. It is written to help you understand which choices will directly affect how long the whole exhaust system can last.

Why the Exhaust Flex Coupler Affects the Overall Exhaust System Life

An exhaust flex coupler is not only used to connect two pipes.Its real role in the system is more like a long-term buffer.During vehicle operation, a flex coupler exhaust is always under three kinds of load: continuous engine vibration, thermal expansion and contraction caused by heating and cooling, and small misalignment from installation tolerances. Each one alone may not look serious, but they work together again and again over time.

When the exhaust flex coupler cannot absorb these movements properly, the stress will move to more rigid parts, such as flange welds, gasket sealing faces, or even the exhaust pipe itself. Many problems that look like “flange leakage” or “cracked weld” are actually caused by wrong flex coupling exhaust selection.

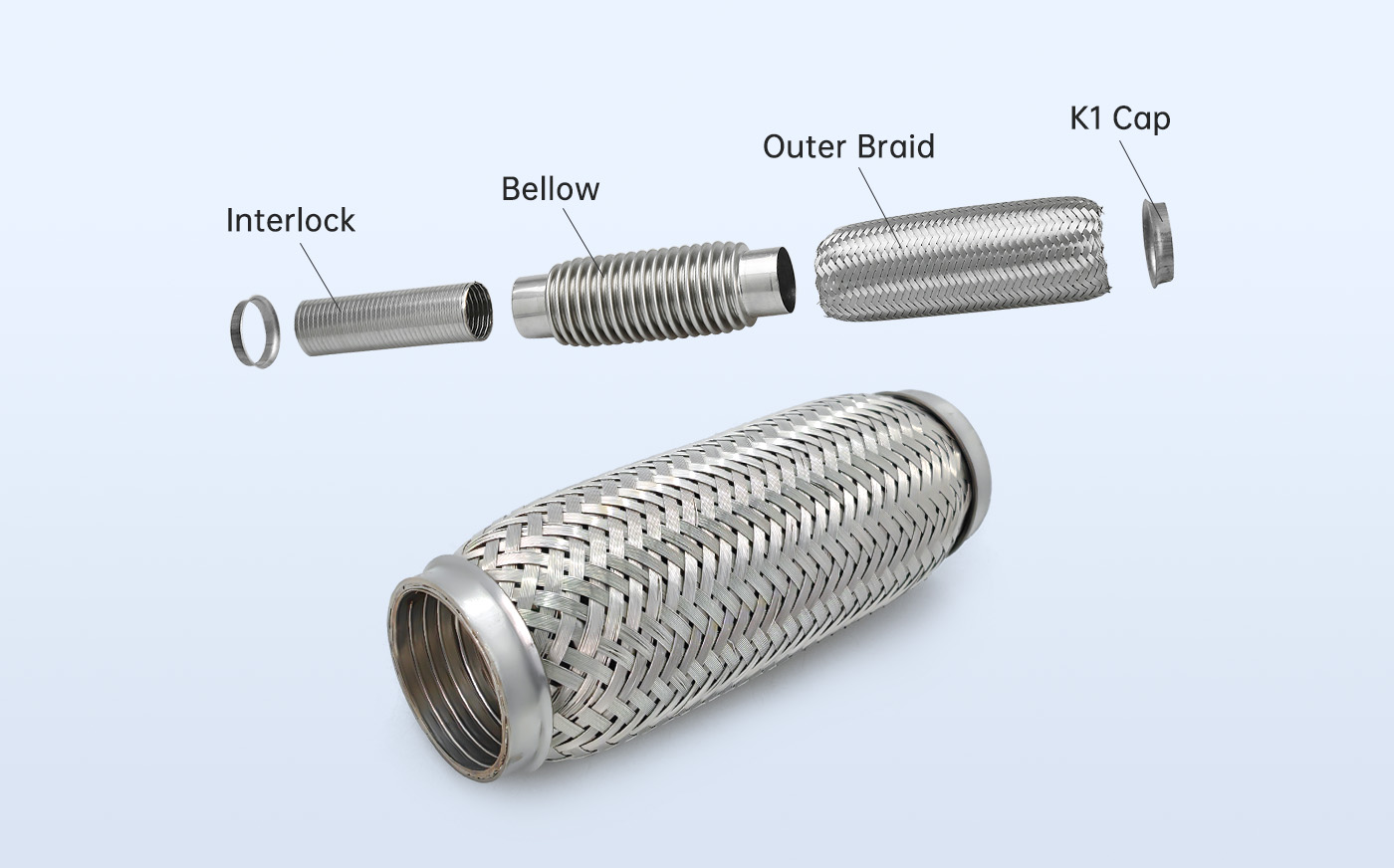

Structure Type — The Real Difference Between Exhaust Flex Couplers

When selecting an exhaust flex coupler, structure often decides service life earlier than material.Common flex exhaust coupling designs can be roughly divided into two types.

Inner Braid Exhaust Flex Coupler

An inner braid exhaust flex coupler uses a braided layer inside the bellows to improve vibration absorption. This structure is friendly to engine vibration and helps reduce vibration transfer to the downstream exhaust system.For passenger cars with frequent stop-and-go driving and naturally aspirated engines, inner braid flex coupling exhaust usually gives stable long-term performance. However, its resistance to very high temperature and pressure is limited. If used outside its design range, service life will drop clearly.

Interlock Exhaust Flex Coupler

Interlock structure uses a metal interlock layer to handle hot and high-speed exhaust flow. Compared with inner braid, it has better resistance to high temperature and pressure, and lower exhaust flow restriction.This type of exhaust flex coupler is more common on turbocharged vehicles, diesel engines, or heavy-duty applications. But stronger does not always mean more suitable. In systems where vibration control is more important, too rigid structure may increase fatigue on other parts.

Why Structure Mismatch Causes More Problems Than Material Choice

Many failures are not caused by weak material, but by wrong matching.Using a high-temperature structure in a vibration-focused system, or using a soft structure in a high-pressure system, will force the exhaust flex coupler to work outside its normal condition, leading to early failure.

Size and Specification — How to Choose the Right Diameter

When searching for products, 2.5 exhaust flex coupler and 3 exhaust flex coupler are the most common keywords. These two sizes cover most passenger cars and light trucks. But for a project, you need to think about more than just the diameter.

2.5 inch Exhaust Flex Coupler: The Standard Choice

The 2.5-inch coupler is the "workhorse" of the industry. It is used in millions of vehicles.

Stable Performance: This size has a very mature design. It offers a great balance between flexibility and strength.

Application: Best for 2.0L to 3.0L engines.

Manufacturer Tip: Even though it is a standard part, we suggest checking the Overall Length. If the engine vibrates a lot, a slightly longer 2.5-inch coupler can help absorb more movement and protect the weld points.

3 inch Exhaust Flex Coupler: For High Flow Needs

The 3-inch version is usually for performance cars or diesel trucks.

Higher Flow: It allows more exhaust gas to pass through, which is good for turbo engines.

Structural Strength: Because the 3-inch pipe is wider and heavier, the flex coupler must be strong enough to support the weight.

Selection Tip: For 3-inch systems, using an Interlock (inner spiral wall) is often better than a simple braid. It helps the exhaust gas flow smoother without turbulence.

Common inner diameter ranges used in practice include:

Nominal ID (Inch) | Metric Equivalent (mm) | Outside Diameter (Approx.) | Typical Application & Flow Capacity | Recommended Installation Tip |

1 3/4" | 45 mm | 48-50 mm | Compact Cars: 1.0L - 1.4L engines. Low flow. | Ensure minimal hang-off to prevent dragging. |

2" | 51 mm | 54-57 mm | Economy Sedans: The standard for 1.6L - 2.0L naturally aspirated engines. | Check for clearance near the oil pan. |

2 1/4" | 57 mm | 60-63 mm | Mid-size SUVs/Sedans: Common in 2.4L engines or dual exhaust setups. | Ideal for balancing backpressure and flow. |

2 1/2" | 63 mm | 67-70 mm | Standard Passenger & V6: High-demand size for 3.0L+ engines. | Best Seller: Most common replacement size. |

3" | 76 mm | 80-83 mm | Performance & Light Trucks: Turbocharged engines and V8 sport exhausts. | Use Interlock structure for high-heat turbo apps. |

3 1/2" | 89 mm | 93-96 mm | Diesel Pickups: Initial downpipe sections for 5.9L/6.7L diesel engines. | Requires heavy-duty double braid support. |

4" | 102 mm | 106-110 mm | Commercial Trucks: Heavy-duty industrial and semi-truck exhaust systems. | Ensure high-quality weld penetration on thick flanges. |

Pro Tip: Measuring for Replacement Don't just measure the flex pipe itself ! To get the perfect fit, measure the Outside Diameter (OD) of your existing exhaust pipe. The Inside Diameter (ID) of the flex coupler should match the OD of your exhaust pipe for a seamless "slip-on" or "butt-weld" fit. Always allow an extra 1/2 inch of length for welding clearance.

Exhaust Flex Coupler Connection Method — Welding, Flange, and No-Weld Options

In repair and modification cases, flange flex coupling exhaust repair pipe is a very common search term. This usually means the system already has problems.

The Real Limit of Flange Repair Pipes

A flange helps with alignment and sealing, but it does not replace the vibration function of an exhaust flex coupler. If the root cause is vibration or thermal movement, adding a flange alone usually only delays the problem.

Clamp-on vs Weld-on Exhaust Flex Coupler

Clamp-on solutions are easy to install and suitable when welding is not possible. However, under long-term vibration, clamped joints are more likely to loosen.

Weld-on flex coupling exhaust gives continuous structure and better load transfer, but welding quality becomes critical. Poor welding can create weak points instead of solving problems.

Common Exhaust Flex Coupler Failure Modes

In many cases, an exhaust flex coupler does not fail in the middle of the bellows, but starts at the weld area.

Heat Affected Zone (HAZ) Around Welds

For example, with 304 stainless steel, if welding heat input is not well controlled, carbide precipitation can appear in the heat affected zone. These areas may look fine at first, but under vibration and thermal cycles, small cracks can slowly develop.

Misalignment and Overstretching

If a flex coupler exhaust is already under offset or tension during installation, its effective service life will be much shorter. Many “only used a few months” failures come from installation conditions.

OEM vs Heavy-Duty Performance Aftermarket

OEM exhaust flex coupling is usually designed for predictable service life under defined conditions, with conservative structure choices.When choosing an exhaust flex coupling, you need to decide between standard OEM-style parts and heavy-duty aftermarket upgrades.

OEM Replacement Parts: We produce a wide range of standard exhaust flex coupler components designed to match original vehicle specs perfectly. These are the best choice for standard repairs where you want the same fit and feel as the factory part.

Heavy-Duty Performance Options: For tougher environments, like turbo engines or heavy trucks, our heavy-duty couplers can handle higher temperatures and stronger vibration. However, they are often "stiffer." Our team can help you decide if an upgrade is necessary for your specific application.

Flange Flex Coupling Exhaust Repair Pipe: One of our most popular solutions is the flange flex coupling exhaust repair pipe. Instead of a simple weld-on pipe, these come with high-quality flanges already attached.

Easy Installation: These are perfect for quick repairs—just bolt them on.

Customization: We have various flange patterns in stock. If you have a specific requirement, we can customize the flange flex coupling according to your drawings or OEM samples.

Whether you need a simple flex coupler exhaust pipe for a passenger car or a custom-flanged assembly for industrial use, the key is choosing the part that fits the system’s real working conditions.

Quick Selection Logic

When facing a real application, start by understanding operating conditions such as vibration, temperature, and pressure. Then choose the structure type, and finally confirm size and connection method. This process usually leads to a more reliable exhaust flex coupler than choosing only by price.

FAQ: Common Questions About Exhaust Flex Coupler

Q: How long should a high-quality exhaust flex coupler last?

A standard exhaust flex coupler should last between 50,000 to 100,000 miles under normal conditions. However, if your engine mounts are worn or you drive on salted roads (causing rust), the flex coupling exhaust may fail sooner. Regular inspection for soot (black marks) or fraying braids is recommended.

Q: Can I use a 2.5 exhaust flex coupler on a 2.25 inch pipe?

It is not recommended. While you can weld it, the size gap will create turbulence and backpressure inside the exhaust flex coupling. This can reduce engine efficiency. Always try to match the ID of the flex coupler exhaust to your pipe's OD for a smooth flow.

Q: Is a stainless steel exhaust flex coupler better than galvanized steel?

Yes. Stainless steel exhaust flex coupler (especially SS304) offers much better resistance to heat and corrosion. Galvanized steel is cheaper but will rust quickly near the welds, leading to exhaust leaks. For any vehicle used in wet or snowy climates, stainless steel is the professional choice.

Q: What is the main cause of flex coupler exhaust pipe failure?

The most common cause is not the part itself, but excessive engine movement. If your engine mounts are soft, the flex coupler exhaust pipe has to bend too far and eventually cracks the internal bellows. Another common cause is poor welding during installation which creates "brittle" spots.

Conclusion: Value Is Found in Service Life

An exhaust flex coupler is a small part, but it has a big job. Its price is low, but the labor cost to replace it is high. Choosing the right technical spec—rather than the cheapest price—prevents repeated repairs and extra downtime. When you treat the selection as a technical decision, you ensure the long-term health of the entire exhaust system.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

INFORMATION

HOT PRODUCTS